Introduction

A few weeks ago I was asked about creating a musical-effect display with an RGB LED cube kit from Freetronics, and with a little work this was certainly possible using the MSGEQ7 spectrum analyser IC. In this project we’ll create a small add-on PCB containing the spectrum analyser circuit and show how it can drive the RGB LED cube kit.

Assumed knowledge

To save repeating myself, please familiarise yourself with the MSGEQ7 spectrum aanalyserIC in Chapter 48 of our Arduino tutorials. And learn more about the LED cube from our review and the product page.

You can get MSGEQ7 ICs from various sources, however they had varying results. We now recommend using the neat module from Tronixlabs.

The circuit

The LED cube already has an Arduino Leonardo-compatible built in to the main PCB, so all you need to do is build a small circuit that contains the spectrum analyzer which connects to the I/O pins on the cube PCB and also has audio input and output connections. First, consider the schematic:

For the purposes of this project our spectrum analyser will only display the results from one channel of audio – if you want stereo, you’ll need two! And note that the strobe, reset and DCOUT pins on the MSGEQ7 are labelled with the connections to the cube PCB. Furthermore the pinouts for the MSGEQ7 don’t match the physical reality – here are the pinouts from the MSGEQ7 data sheet (.pdf):

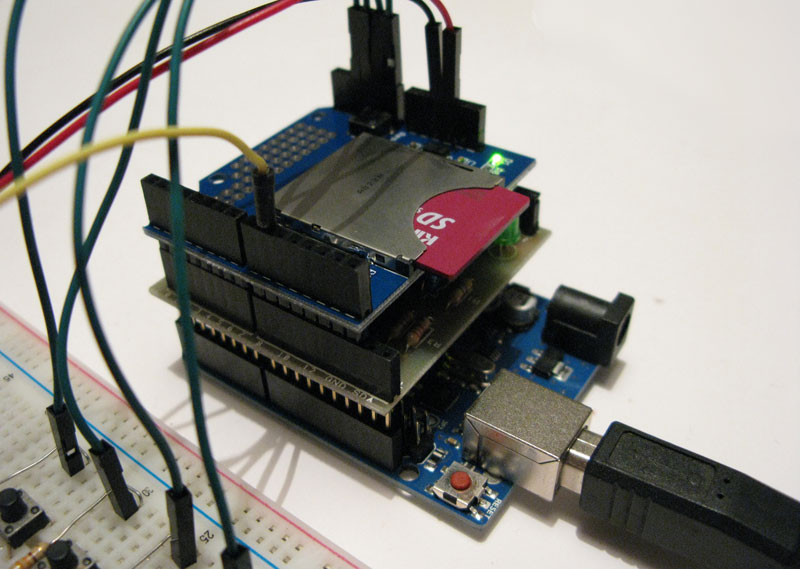

The circuit itself will be quite small and fit on a small amount of stripboard or veroboard. There is plenty of room underneath the cube to fit the circuit if so desired:

With a few moments you should be able to trace out your circuit to match the board type you have, remember to double-check before soldering. You will also need to connect the audio in point after the 1000 pF capacitor to a source of audio, and also pass it through so you can connect powered speakers, headphones, etc.

One method of doing so would be to cut up a male-female audio extension lead, and connect the shield to the GND of the circuit, and the signal line to the audio input on the circuit. Or if you have the parts handy and some shielded cable, just make your own input and output leads:

Be sure to test for shorts between the signal and shield before soldering to the circuit board. When finished, you should have something neat that you can hide under the cube or elsewhere:

Double-check your soldering for shorts and your board plan, then fit to the cube along with the audio source and speakers (etc).

Arduino Sketch

The sketch has two main functions – the first is to capture the levels from the MSGEQ7 and put the values for each frequency band into an array, and the second function is to turn on LEDs that represent the level for each band. If you’ve been paying attention you may be wondering how we can represent seven frequency bands with a 4x4x4 LED cube. Simple – by rotating the cube 45 degrees you can see seven vertical columns of LEDs:

So when looking from the angle as shown above, you have seven vertical columns, each with four levels of LEDs. Thus the strength of each frequency can be broken down into four levels, and then the appropriate LEDs turned on.

After this is done for each band, all the LEDs are turned off and the process repeats. For the sake of simplicity I’ve used the cube’s Arduino library to activate the LEDs, which also makes the sketch easier to fathom. The first example sketch only uses one colour:

// Freetronics CUBE4: and MSGEQ7 spectrum analyser

// MSGEQ7 strobe on A4, reset on D5, signal into A0

#include "SPI.h"

#include "Cube.h"

Cube cube;

int res = 5; // reset pins on D5

int left[7]; // store band values in these arrays

int band;

void setup()

{

pinMode(res, OUTPUT); // reset

pinMode(A4, OUTPUT); // strobe

digitalWrite(res,LOW);

digitalWrite(A4,HIGH);

cube.begin(-1, 115200);

Serial.begin(9600);

}

void readMSGEQ7()

// Function to read 7 band equalizers

{

digitalWrite(res, HIGH);

digitalWrite(res, LOW);

for(band=0; band <7; band++)

{

digitalWrite(A4,LOW); // strobe pin on the shield - kicks the IC up to the next band

delayMicroseconds(30); //

left[band] = analogRead(0); // store band reading

digitalWrite(A4,HIGH);

}

}

void loop()

{

readMSGEQ7();

for (band = 0; band < 7; band++)

{

// div each band strength into four layers, each band then one of the odd diagonals

// band one ~ 63 Hz

if (left[0]>=768) {

cube.set(3,3,3, BLUE);

}

else

if (left[0]>=512) {

cube.set(3,3,2, BLUE);

}

else

if (left[0]>=256) {

cube.set(3,3,1, BLUE);

}

else

if (left[0]>=0) {

cube.set(3,3,0, BLUE);

}

// band two ~ 160 Hz

if (left[1]>=768)

{

cube.set(3,2,3, BLUE);

cube.set(2,3,3, BLUE);

}

else

if (left[1]>=512)

{

cube.set(3,2,2, BLUE);

cube.set(2,3,2, BLUE);

}

else

if (left[1]>=256)

{

cube.set(3,2,1, BLUE);

cube.set(2,3,1, BLUE);

}

else

if (left[1]>=0)

{

cube.set(3,2,0, BLUE);

cube.set(2,3,0, BLUE);

}

// band three ~ 400 Hz

if (left[2]>=768)

{

cube.set(3,1,3, BLUE);

cube.set(2,2,3, BLUE);

cube.set(1,3,3, BLUE);

}

else

if (left[2]>=512)

{

cube.set(3,1,2, BLUE);

cube.set(2,2,2, BLUE);

cube.set(1,3,2, BLUE);

}

else

if (left[2]>=256)

{

cube.set(3,1,1, BLUE);

cube.set(2,2,1, BLUE);

cube.set(1,3,1, BLUE);

}

else

if (left[2]>=0)

{

cube.set(3,1,0, BLUE);

cube.set(2,2,0, BLUE);

cube.set(1,3,0, BLUE);

}

// band four ~ 1 kHz

if (left[3]>=768)

{

cube.set(3,0,3, BLUE);

cube.set(2,1,3, BLUE);

cube.set(1,2,3, BLUE);

cube.set(0,3,3, BLUE);

}

else

if (left[3]>=512)

{

cube.set(3,0,2, BLUE);

cube.set(2,1,2, BLUE);

cube.set(1,2,2, BLUE);

cube.set(0,3,2, BLUE);

}

else

if (left[3]>=256)

{

cube.set(3,0,1, BLUE);

cube.set(2,1,1, BLUE);

cube.set(1,2,1, BLUE);

cube.set(0,3,1, BLUE);

}

else

if (left[3]>=0)

{

cube.set(3,0,0, BLUE);

cube.set(2,1,0, BLUE);

cube.set(1,2,0, BLUE);

cube.set(0,3,0, BLUE);

}

// band five ~ 2.5 kHz

if (left[4]>=768)

{

cube.set(2,0,3, BLUE);

cube.set(1,1,3, BLUE);

cube.set(0,2,3, BLUE);

}

else

if (left[4]>=512)

{

cube.set(2,0,2, BLUE);

cube.set(1,1,2, BLUE);

cube.set(0,2,2, BLUE);

}

else

if (left[4]>=256)

{

cube.set(2,0,1, BLUE);

cube.set(1,1,1, BLUE);

cube.set(0,2,1, BLUE);

}

else

if (left[4]>=0)

{

cube.set(2,0,0, BLUE);

cube.set(1,1,0, BLUE);

cube.set(0,2,0, BLUE);

}

// band six ~ 6.25 kHz

if (left[5]>=768)

{

cube.set(1,0,3, BLUE);

cube.set(0,1,3, BLUE);

}

else

if (left[5]>=512)

{

cube.set(1,0,2, BLUE);

cube.set(0,1,2, BLUE);

}

else

if (left[5]>=256)

{

cube.set(1,0,1, BLUE);

cube.set(0,1,1, BLUE);

}

else

if (left[5]>=0)

{

cube.set(1,0,0, BLUE);

cube.set(0,1,0, BLUE);

}

// band seven ~ 16 kHz

if (left[6]>=768)

{

cube.set(0,0,3, BLUE);

}

else

if (left[6]>=512)

{

cube.set(0,0,2, BLUE);

}

else

if (left[6]>=256)

{

cube.set(0,0,1, BLUE);

}

else

if (left[6]>=0)

{

cube.set(0,0,0, BLUE);

}

}

// now clear the CUBE, or if that's too slow - repeat the process but turn LEDs off

cube.all(BLACK);

}… and a quick video demonstration:

For a second example, we’ve used various colours:

// Freetronics CUBE4: and MSGEQ7 spectrum analyser

// MSGEQ7 strobe on A4, reset on D5, signal into A0

// now in colour!

#include "SPI.h"

#include "Cube.h"

Cube cube;

int res = 5; // reset pins on D5

int left[7]; // store band values in these arrays

int band;

int additional=0;

void setup()

{

pinMode(res, OUTPUT); // reset

pinMode(A4, OUTPUT); // strobe

digitalWrite(res,LOW);

digitalWrite(A4,HIGH);

cube.begin(-1, 115200);

Serial.begin(9600);

}

void readMSGEQ7()

// Function to read 7 band equalizers

{

digitalWrite(res, HIGH);

digitalWrite(res, LOW);

for(band=0; band <7; band++)

{

digitalWrite(A4,LOW); // strobe pin on the shield - kicks the IC up to the next band

delayMicroseconds(30); //

left[band] = analogRead(0) + additional; // store band reading

digitalWrite(A4,HIGH);

}

}

void loop()

{

readMSGEQ7();

for (band = 0; band < 7; band++)

{

// div each band strength into four layers, each band then one of the odd diagonals

// band one ~ 63 Hz

if (left[0]>=768) {

cube.set(3,3,3, RED);

}

else

if (left[0]>=512) {

cube.set(3,3,2, YELLOW);

}

else

if (left[0]>=256) {

cube.set(3,3,1, YELLOW);

}

else

if (left[0]>=0) {

cube.set(3,3,0, BLUE);

}

// band two ~ 160 Hz

if (left[1]>=768)

{

cube.set(3,2,3, RED);

cube.set(2,3,3, RED);

}

else

if (left[1]>=512)

{

cube.set(3,2,2, YELLOW);

cube.set(2,3,2, YELLOW);

}

else

if (left[1]>=256)

{

cube.set(3,2,1, YELLOW);

cube.set(2,3,1, YELLOW);

}

else

if (left[1]>=0)

{

cube.set(3,2,0, BLUE);

cube.set(2,3,0, BLUE);

}

// band three ~ 400 Hz

if (left[2]>=768)

{

cube.set(3,1,3, RED);

cube.set(2,2,3, RED);

cube.set(1,3,3, RED);

}

else

if (left[2]>=512)

{

cube.set(3,1,2, YELLOW);

cube.set(2,2,2, YELLOW);

cube.set(1,3,2, YELLOW);

}

else

if (left[2]>=256)

{

cube.set(3,1,1, YELLOW);

cube.set(2,2,1, YELLOW);

cube.set(1,3,1, YELLOW);

}

else

if (left[2]>=0)

{

cube.set(3,1,0, BLUE);

cube.set(2,2,0, BLUE);

cube.set(1,3,0, BLUE);

}

// band four ~ 1 kHz

if (left[3]>=768)

{

cube.set(3,0,3, RED);

cube.set(2,1,3, RED);

cube.set(1,2,3, RED);

cube.set(0,3,3, RED);

}

else

if (left[3]>=512)

{

cube.set(3,0,2, YELLOW);

cube.set(2,1,2, YELLOW);

cube.set(1,2,2, YELLOW);

cube.set(0,3,2, YELLOW);

}

else

if (left[3]>=256)

{

cube.set(3,0,1, YELLOW);

cube.set(2,1,1, YELLOW);

cube.set(1,2,1, YELLOW);

cube.set(0,3,1, YELLOW);

}

else

if (left[3]>=0)

{

cube.set(3,0,0, BLUE);

cube.set(2,1,0, BLUE);

cube.set(1,2,0, BLUE);

cube.set(0,3,0, BLUE);

}

// band five ~ 2.5 kHz

if (left[4]>=768)

{

cube.set(2,0,3, RED);

cube.set(1,1,3, RED);

cube.set(0,2,3, RED);

}

else

if (left[4]>=512)

{

cube.set(2,0,2, YELLOW);

cube.set(1,1,2, YELLOW);

cube.set(0,2,2, YELLOW);

}

else

if (left[4]>=256)

{

cube.set(2,0,1, YELLOW);

cube.set(1,1,1, YELLOW);

cube.set(0,2,1, YELLOW);

}

else

if (left[4]>=0)

{

cube.set(2,0,0, BLUE);

cube.set(1,1,0, BLUE);

cube.set(0,2,0, BLUE);

}

// band six ~ 6.25 kHz

if (left[5]>=768)

{

cube.set(1,0,3, RED);

cube.set(0,1,3, RED);

}

else

if (left[5]>=512)

{

cube.set(1,0,2, YELLOW);

cube.set(0,1,2, YELLOW);

}

else

if (left[5]>=256)

{

cube.set(1,0,1, YELLOW);

cube.set(0,1,1, YELLOW);

}

else

if (left[5]>=0)

{

cube.set(1,0,0, BLUE);

cube.set(0,1,0, BLUE);

}

// band seven ~ 16 kHz

if (left[6]>=768)

{

cube.set(0,0,3, RED);

}

else

if (left[6]>=512)

{

cube.set(0,0,2, YELLOW);

}

else

if (left[6]>=256)

{

cube.set(0,0,1, YELLOW);

}

else

if (left[6]>=0)

{

cube.set(0,0,0, BLUE);

}

}

// now clear the CUBE, or if that's too slow - repeat the process but turn LEDs off

cube.all(BLACK);

}… and the second video demonstration:

A little bit of noise comes through into the spectrum analyser, most likely due to the fact that the entire thing is unshielded. The previous prototype used the Arduino shield from the tutorial which didn’t have this problem, so if you’re keen perhaps make your own custom PCB for this project.

xxxxxxx

Conclusion

Well that was something different and I hope you enjoyed it, and can find use for the circuit. That MSGEQ7 is a handy IC and with some imagination you can create a variety of musically-influenced displays. And if you enjoyed this article, or want to introduce someone else to the interesting world of Arduino – check out my book (now in a fourth printing!) “Arduino Workshop”.

Have fun and keep checking into tronixstuff.com. Why not follow things on twitter, Google+, subscribe for email updates or RSS using the links on the right-hand column, or join our forum – dedicated to the projects and related items on this website.

The post Project – LED Cube Spectrum Analyzer appeared first on tronixstuff.