Hackaday Prize Entry: Head-up For High Voltage

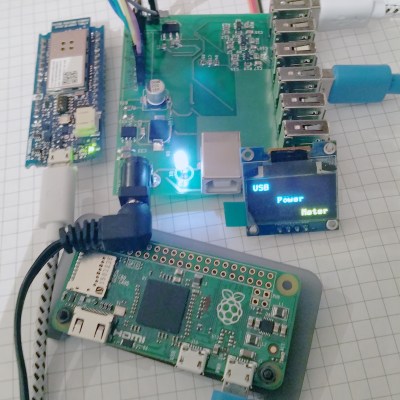

[Alain Mauer] wanted to build something like a Google Glass setup using a small OLED screen. A 0.96 inch display was too large, but a 0.66 inch one worked well. Combining an Arduino, a Bluetooth module, and battery, and some optics, he built glasses that will show the readout from a multimeter.

You’d think it was simple to pull this off, but it isn’t for a few reasons as [Alain] discovered. The device cost about 70 Euro and you can see a video of the result, below.

The video shows a common problem and its solution. You are probing a mains circuit and have to look away to read the voltmeter. With the glasses, you don’t have to look away, the voltage floats in your field of vision.

These reminded us of Pedosaglass which we covered earlier. Of course, it used a different optical solution. We’ve also seen Google Glass knockoffs as part of our Hackaday prize entries.

Filed under: Arduino Hacks, The Hackaday Prize, wearable hacks