Tutorial – Arduino and SIM900 GSM Modules

Use the SIM900 GSM modules with Arduino in Chapter 55 of our Arduino Tutorials. The first chapter is here, the complete series is detailed here.

Introduction

The goal of this tutorial is to illustrate various methods of interaction between an Arduino Uno (or compatible) and the GSM cellular network using a SIM900 GSM shield, with which you can then use your existing knowledge to build upon those methods.

We’ll be using a SIMCOM SIM900 GSM module shield. (If you’re looking for tutorials on the Spreadtrum SM5100 modules, start here). There must be scores of Arduino shields or modules using the SIM900, so as you can imagine each one may be a little bit different with regards to the hardware side of things – so we’re assuming you have an understanding of how hardware and software serial works as well as supply voltages and the hardware side of the Arduino world.

As for the specific shield to use, we just chose the cheapest one available at the time – which turned out to be the “SIM900 GPRS/GSM Arduino shield” from Linksprite:

However with a little research and work, the sketches provided should also work with any SIM900 module/shield and Arduino – as long as you have the appropriate serial and power settings.

Getting Started

A little preparation goes a long way, so make sure you’ve covered the following points:

- Regarding your cellular provider. Do you have coverage on a GSM 850 MHz, GSM 900 MHz, DCS 1800 MHz or PCS 1900 MHz network? When we say GSM that means 2G – not 3G, 4G or LTE. Will they allow the use of non-supported devices on the network? Some carriers will block IMEI numbers that were not provided by their sales channel. Or you may have to call the provider and supply the IMEI of your GSM module to allow it on the network. Finally, it would be wise to use either a prepaid or an account that offers unlimited SMS text messaging – you don’t want any large bills if things go wrong.

- Power. Do you have adequate power for your SIM900 module? Some shields will use more current than the Arduino can supply (up to 2A), so you may need an external high-current supply. The Linksprite shield we use needs 5V up to 2A into the onboard DC socket. Otherwise, check with your supplier.

- Antenna. If your module/shield etc. doesn’t have an antenna – get one. You do need it.

- Turn off the PIN lock on the SIM card. The easiest way to do this is to put the SIM in a handset and use the menu function.

- And as always, please don’t make an auto-dialler…

Furthermore, download the SIM900 hardware manual (.pdf) and the AT command manual (.pdf), as we’ll refer to those throughout the tutorial.

Power

There is a DC socket on the shield, which is for a 5V power supply:

Although the data from Linksprite claims the shield will use no more than 450 mA, the SIMCOM hardware manual (page 22) for the module notes that it can draw up to 2A for short bursts. So get yourself a 5V 2A power supply and connect it via the DC socket, and also ensure the switch next to the socket is set to “EXT”.

Furthermore, you can turn the GSM module on and off with the power button on the side of the shield, and it defaults to off during an initial power-up. Therefore you’ll need to set D9 to HIGH for one second in your sketch to turn the module on (or off if required for power-saving). Don’t panic, we’ll show how this is done in the sketches below.

Software Serial

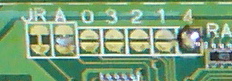

We will use the Arduino software serial library in this tutorial, and the Linksprite shield has hard-wired the serial from the SIM900 to a set of jumpers, and uses a default speed of 19200. Make sure you your jumpers are set to the “SWserial” side, as shown below:

And thus whenever an instance of SoftwareSerial is created, we use 7,8 as shown below:

SoftwareSerial SIM900(7, 8); // RX, TX

If you shield is different, you’ll need to change the TX and RX pin numbers. This also means you can’t use an Arduino Leonardo or Mega (easily).

Wow – all those rules and warnings?

The sections above may sound a little authoritarian, however we want your project to be a success. Now, let’s get started…

A quick test…

At this point we’ll check to make sure your shield and locate and connect to the cellular network. So make sure your SIM card is active with your cellular provider, the PIN lock is off, and then insert it and lock the SIM card to the carrier on the bottom of the shield:

Then plug the shield into your Uno, attach 5V power to the DC socked on the GSM shield, and USB from the Uno to the PC. Press the “PWRKEY” button on the side of the shield for a second, then watch the following two LEDs:

The bright “STATUS” LED will come on, and then the “NETLIGHT” LED will blink once every 800 milliseconds- until the GSM module has found the network, at which point it will blink once every three seconds. This is shown in the following video:

Nothing can happen until that magic three-second blink – so if that doesn’t appear after a minute, something is wrong. Check your shield has the appropriate power supply, the antenna is connected correctly, the SIM card is seated properly and locked in- and that your cellular account is in order. Finally, you may not have reception in that particular area, so check using a phone on the same network or move to a different location.

Making a telephone call from your Arduino

You can have your Arduino call a telephone number, wait a moment – then hang up. This is an inexpensive way of alerting you of and consider the following sketch:

// Example 55.1

#include <SoftwareSerial.h>

SoftwareSerial SIM900(7, 8); // configure software serial port

void setup()

{

SIM900.begin(19200);

SIM900power();

delay(20000); // give time to log on to network.

}

void SIM900power()

// software equivalent of pressing the GSM shield "power" button

{

digitalWrite(9, HIGH);

delay(1000);

digitalWrite(9, LOW);

delay(5000);

}

void callSomeone()

{

SIM900.println("ATD + +12128675309;"); // dial US (212) 8675309

delay(100);

SIM900.println();

delay(30000); // wait for 30 seconds...

SIM900.println("ATH"); // hang up

}

void loop()

{

callSomeone(); // call someone

SIM900power(); // power off GSM shield

do {} while (1); // do nothing

}The sketch first creates a software serial port, then in void setup() starts the software serial port, and also turns on the GSM shield with the function SIM900power (which simply sets D9 high for a second which is the equivalent of pressing the power button). Notice the delay function in void setup – this gives the GSM module a period of time to locate and log on to the cellular network. You may need to increase (or be able to decrease) the delay value depending on your particular situation. If in doubt, leave it as a long period.

The process of actually making the call is in the function callSomeone(). It sends a string of text to the GSM module which consists of an AT command. These are considered the “language” for modems and thus used for various tasks. We use the ATD command to dial (AT… D for dial) a number. The number as you can see in the sketch needs to be in world-format. So that’s a “+” then the country code, then the phone number with area code (without the preceding zero).

So if your number to call is Australia (02) 92679111 you would enter +61292679111. Etcetera. A carriage return is then sent to finalise the command and off it goes dialling the number. Here’s a quick video demonstration for the non-believers:

After thirty seconds we instruct the module to hand up with another AT command – “ATH” (AT… H for “hang up”), followed by turning off the power to the module. By separating the call feature into a function – you can now insert this into a sketch (plus the preceding setup code) to call a number when required.

Sending an SMS text message

This is a great way of getting data from your Arduino to almost any mobile phone in the world, at a very low cost. For reference, the maximum length of an SMS text message is 160 characters – however you can still say a lot with that size limit. First we’ll demonstrate sending an arbitrary SMS. Consider the following sketch:

// Example 55.2

#include <SoftwareSerial.h>

SoftwareSerial SIM900(7, 8);

void setup()

{

SIM900.begin(19200);

SIM900power();

delay(20000); // give time to log on to network.

}

void SIM900power()

// software equivalent of pressing the GSM shield "power" button

{

digitalWrite(9, HIGH);

delay(1000);

digitalWrite(9, LOW);

delay(5000);

}

void sendSMS()

{

SIM900.print("AT+CMGF=1\r"); // AT command to send SMS message

delay(100);

SIM900.println("AT + CMGS = \"+12128675309\""); // recipient's mobile number, in international format

delay(100);

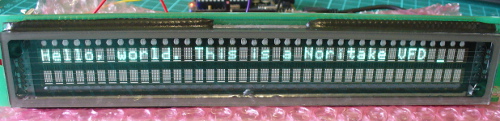

SIM900.println("Hello, world. This is a text message from an Arduino Uno."); // message to send

delay(100);

SIM900.println((char)26); // End AT command with a ^Z, ASCII code 26

delay(100);

SIM900.println();

delay(5000); // give module time to send SMS

SIM900power(); // turn off module

}

void loop()

{

sendSMS();

do {} while (1);

}The basic structure and setup functions of the sketch are the same as the previous example, however the difference here is the function sendSMS(). It used the AT command “AT+CMGF” to tell the GSM module we want to send an SMS in text form, and then “AT+CMGS” followed by the recipient’s number. Once again note the number is in international format. After sending the send SMS commands, the module needs five seconds to do this before we can switch it off. And now for our ubiquitous demonstration video:

You can also send text messages that are comprised of numerical data and so on – by compiling the required text and data into a string, and then sending that. Doing so gives you a method to send such information as sensor data or other parameters by text message.

For example, you might want to send daily temperature reports or hourly water tank levels. For our example, we’ll demonstrate how to send a couple of random numbers and some text as an SMS. You can then use this as a framework for your own requirements. Consider the following sketch:

// Example 55.3

#include <SoftwareSerial.h>

SoftwareSerial SIM900(7, 8);

int x,y;

String textForSMS;

void setup()

{

SIM900.begin(19200);

SIM900power();

delay(20000); // give time to log on to network.

randomSeed(analogRead(0));

}

void SIM900power()

// software equivalent of pressing the GSM shield "power" button

{

digitalWrite(9, HIGH);

delay(1000);

digitalWrite(9, LOW);

delay(7000);

}

void sendSMS(String message)

{

SIM900.print("AT+CMGF=1\r"); // AT command to send SMS message

delay(100);

SIM900.println("AT + CMGS = \"+12128675309\""); // recipient's mobile number, in international format

delay(100);

SIM900.println(message); // message to send

delay(100);

SIM900.println((char)26); // End AT command with a ^Z, ASCII code 26

delay(100);

SIM900.println();

delay(5000); // give module time to send SMS

SIM900power(); // turn off module

}

void loop()

{

x = random(0,255);

y = random(0,255);

textForSMS = "Your random numbers are ";

textForSMS.concat(x);

textForSMS = textForSMS + " and ";

textForSMS.concat(y);

textForSMS = textForSMS + ". Enjoy!";

sendSMS(textForSMS);

do {} while (1);

}Take note of the changes to the function sendSMS(). It now has a parameter – message, which is a String which contains the text to send as an SMS. In void loop() the string variable textForSMS is constructed. First it contains some text, then the values for x and y are added with some more text. Finally the string is passed to be sent as an SMS. And here it is in action:

Conclusion

After working through this tutorial you should have an understanding of how the basics of the GSM shield and AT commands work. If there’ s demand we’ll continue with more features and possibilities in a future tutorial, so let us know via the contact page. And if you enjoyed the tutorial, or want to introduce someone else to the interesting world of Arduino – check out my book (now in a third printing!) “Arduino Workshop” from No Starch Press.

In the meanwhile have fun and keep checking into tronixstuff.com. Why not follow things on twitter, Google+, subscribe for email updates or RSS using the links on the right-hand column? And join our friendly Google Group – dedicated to the projects and related items on this website. Sign up – it’s free, helpful to each other – and we can all learn something.

The post Tutorial – Arduino and SIM900 GSM Modules appeared first on tronixstuff.