Electrical engineer Chris Gammell has spent almost a year creating his new online electronics program called “Contextual Electronics“, and we’re excited to share this with our readers. You may have heard of Chris from his regular successful podcast with Dave Jones – “The Amp Hour“.

Chris has the knowledge and expertise to take electronic ideas from simply that – an idea, right through to production. And by participating in his Contextual Electronics program you can learn the required skills to do this as well. Chris gives us a quick introduction in this video.

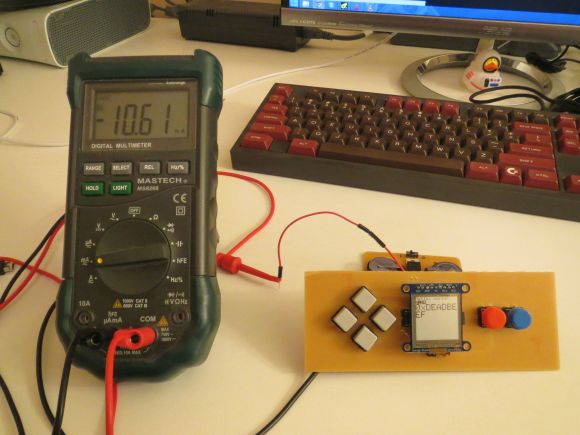

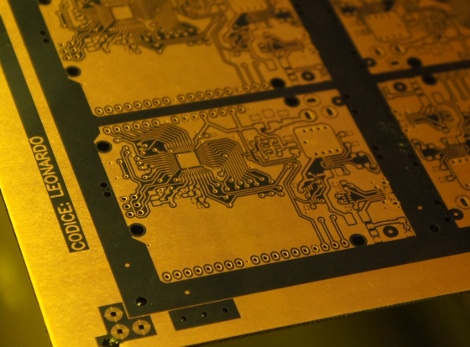

Contextual Electronics is a new program aimed at electronics enthusiasts who are ready to take their Arduino (or similar platform) skills to the next level. The first session of the course is an 8 week program that will teach you how to design a large, multi-function Arduino shield using KiCad, the open source CAD software.

It will also show you all of the design decisions that go into making the project. Here are some of the sub-circuits included in the 4-layer PCB design:

- High level signals measurement using op-amps

The course has a large community component, so you will be grouped with others learning at the same time, regardless of where you’re located in the world. The goal of the course and the community aspect is to make you more confident designing a project so you can go and design your own.

Future sessions of the course will also go over building, troubleshooting and coding for the shield described above. There is also a free short course that you can review to give you an idea of Chris’ methods and what the Contextual Electronics program will be like.

Additional courses will be developed using other popular development boards, including the Raspberry Pi and BeagleBone. For a more in-depth introduction, check out this video.

Frankly the program will help all of you who are ready to take your ideas and projects off the breadboard and into finished products, and with the guidance available with the program and the use of open-source tools you’ll be up and making things you can be proud of showing to friends or even potential employers. For more information about the program, and to sign up – visit the Contextual Electronics program website.

And if you enjoyed this article, or want to introduce someone else to the interesting world of Arduino – check out my book (now in a third printing!) “Arduino Workshop”.

Have fun and keep checking into

tronixstuff.com. Why not follow things on

twitter,

Google+, subscribe for email updates or RSS using the links on the right-hand column, or join our

forum – dedicated to the projects and related items on this website.

Sign up – it’s free, helpful to each other – and we can all learn something.

The post Learn electronics with Chris Gammell and “Contextual Electronics” appeared first on tronixstuff.

Several years ago, Chris Gregg, a Tufts University lecturer and computer engineer, received a letter from his friend Erica. This wouldn’t be so unusual, except that it was typed on an actual typewriter, not a printer. Gregg is a fan of vintage typewriters, but, as with myself, makes many mistakes, […]

Several years ago, Chris Gregg, a Tufts University lecturer and computer engineer, received a letter from his friend Erica. This wouldn’t be so unusual, except that it was typed on an actual typewriter, not a printer. Gregg is a fan of vintage typewriters, but, as with myself, makes many mistakes, […]