Small CNC machines for customizing coasters

As seen on Make:, Barton Dring wanted to make something interesting to bring to a hardware meetup, along with learning more about the Grbl Arduino machining package. What he came up with was a pair of drawing robots that are both small enough to fit inside of a backpack, and are used to decorate coasters!

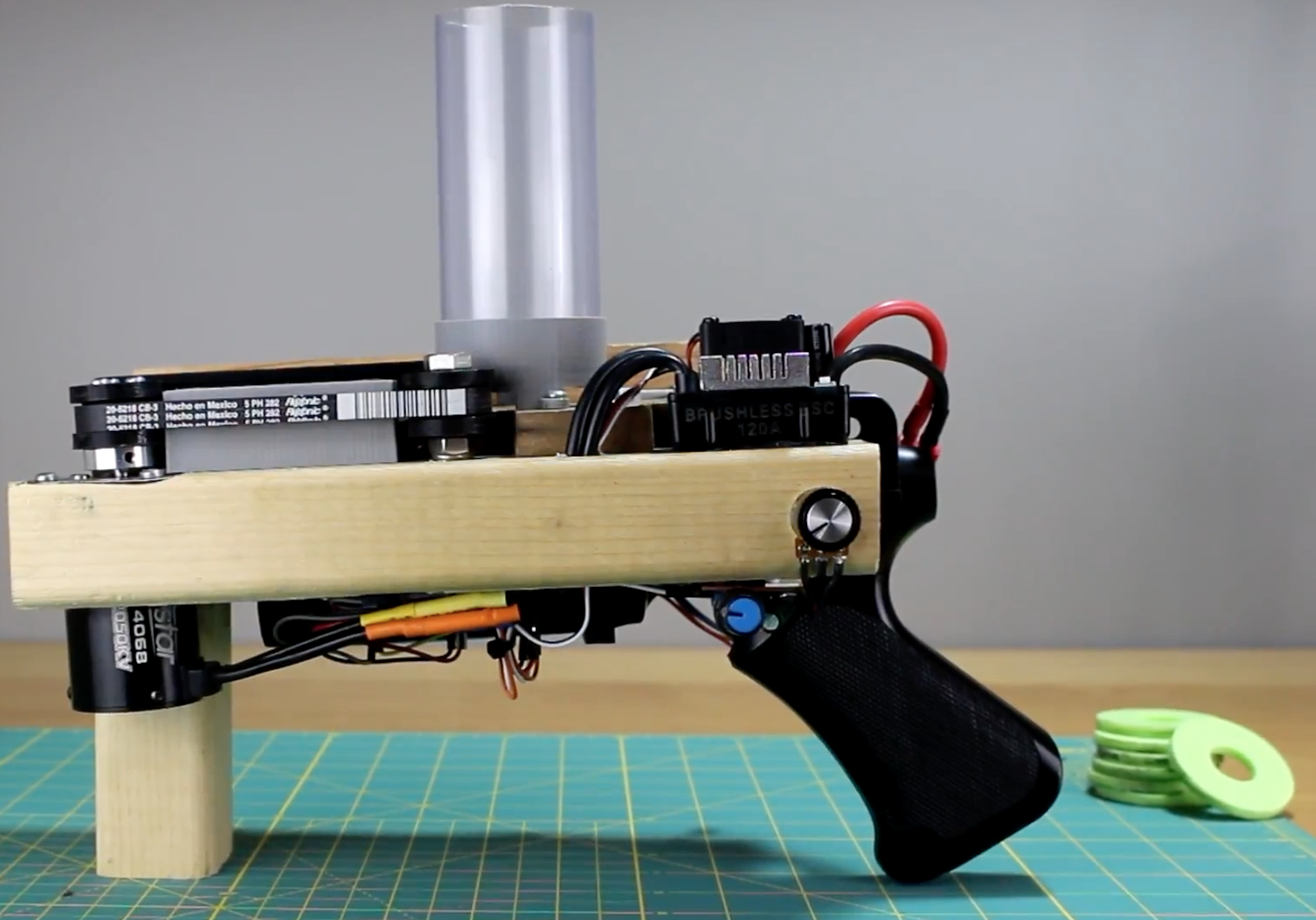

The first of these projects, known as “Coasty,” employs a laser to mark, or even cut, square coasters. They are fed in from the side, then pop out again with a new pattern.

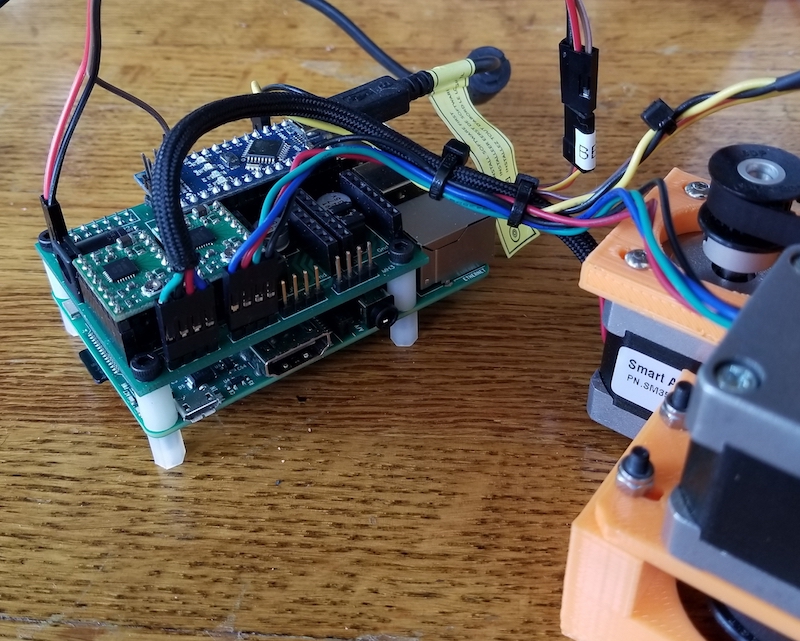

The second device uses a much different method, showing off Grbl’s versatility as a polar plotter. Round coasters are placed on a rotating base, and a pen goes around and around until a new doodle is produced.

Be sure to check out both of these machines in action in the videos below!