Open Source Hackable Robot

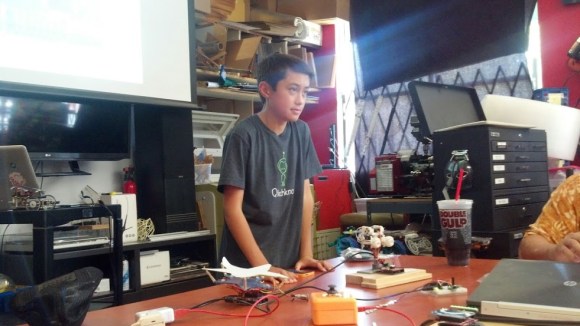

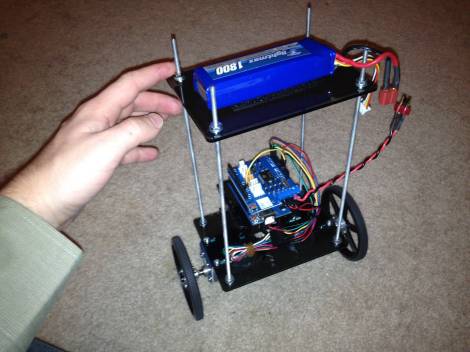

The world of robots is an interesting place, and it’s an even better place for children to get started in electronics. To that end, [Richard Albritton] has created a low-cost, open source robotics platform called the Hack-E-Bot specifically tailored to make it as easy as possible to get started.

The goals for the robot kit were to spark curiosity for electronics and programming, to be easy to assemble and program, to be scalable, and to be as easy on the wallet as possible. This was accomplished by using the familiar Arduino microcontroller on an intuitive platform. The robot uses an ultrasonic rangefinder to navigate as well, and can support a wide range of other sensors. The kit comes in at just under $50, making it a great option for an entry-level robot.

The project is currently seeking crowd funding and [Richard] is also seeking educators to get involved. Currently the only kits available are at fairs and other conventions but they should be able to start producing them in greater quantities in the future. The Arduino libraries are a work in progress but they are available on the project site, as well as several instructional videos and other information about the project.

Filed under: robots hacks