A surfing “desk toy” that you can actually ride

If you’ve ever played with desk toys portraying a beach with liquids that splash around, this project by Lena Strobel, Gabriel Rihaczek and Guillaume Caussarieu takes things up several levels as a surf simulator that you can actually ride.

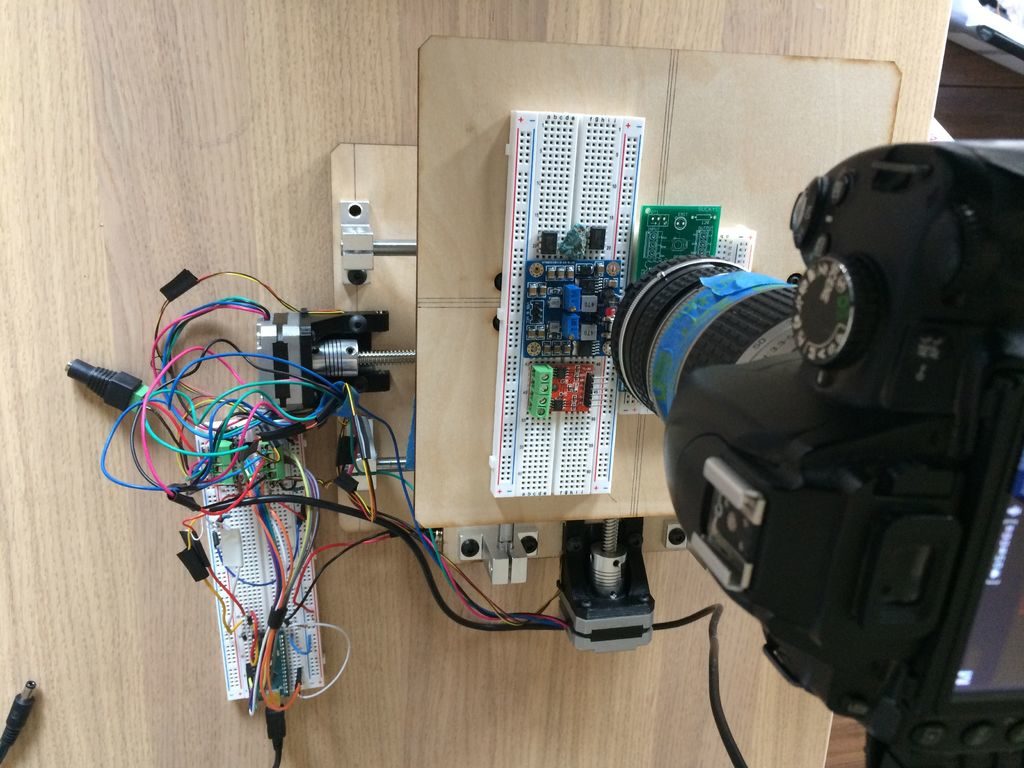

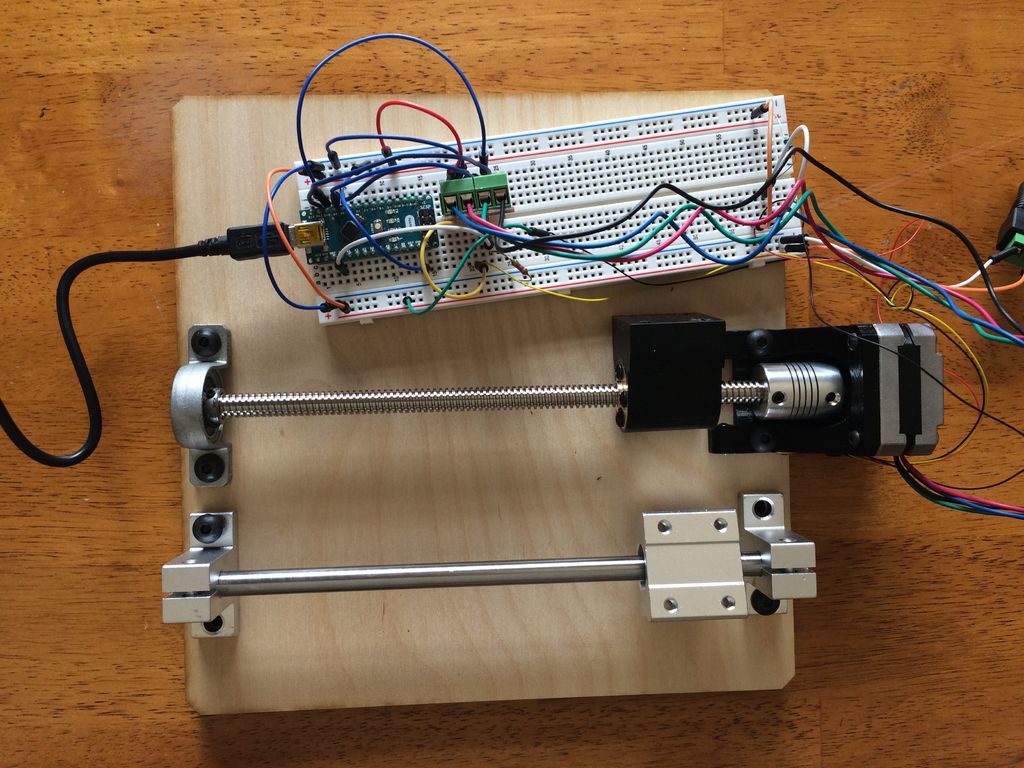

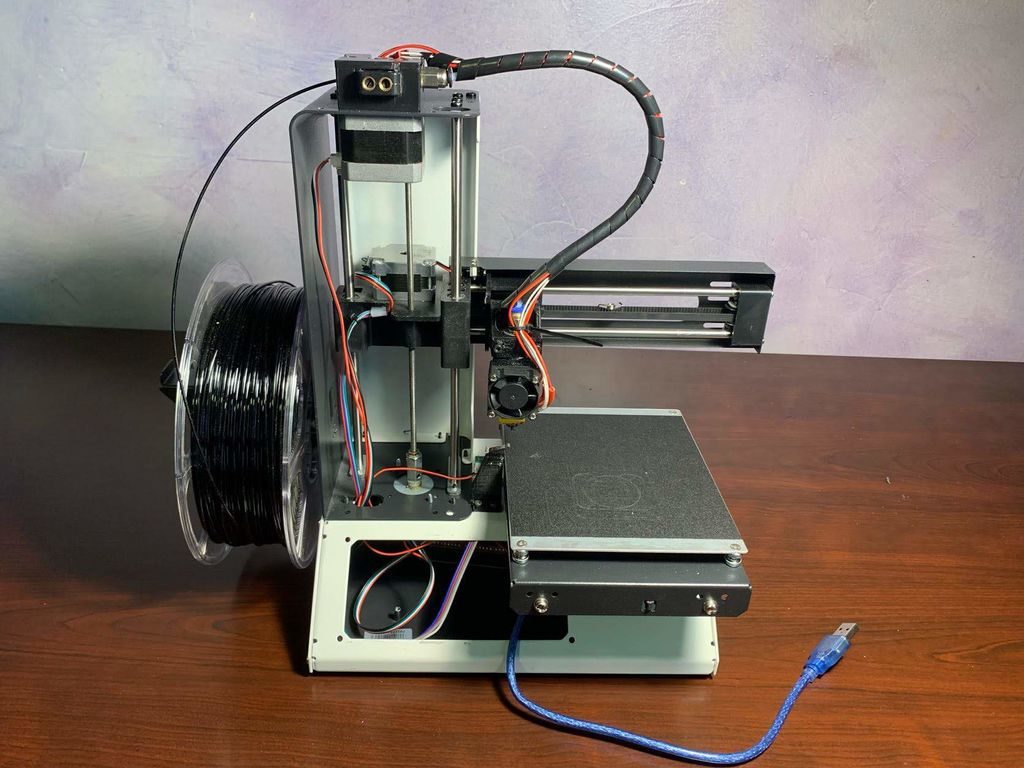

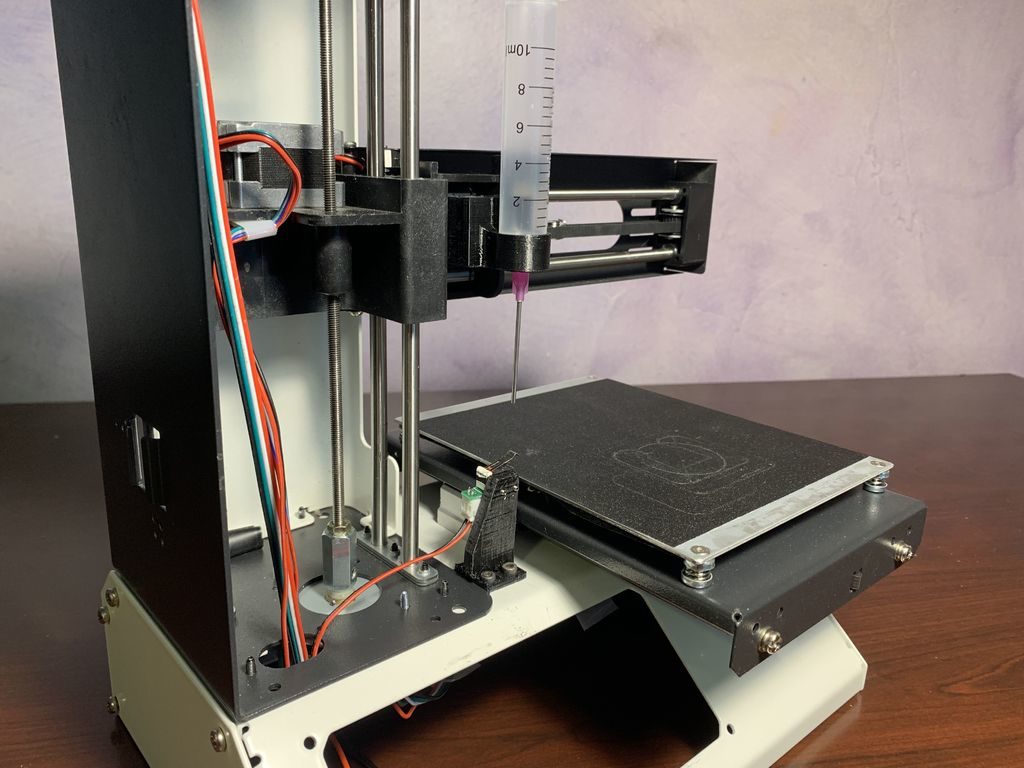

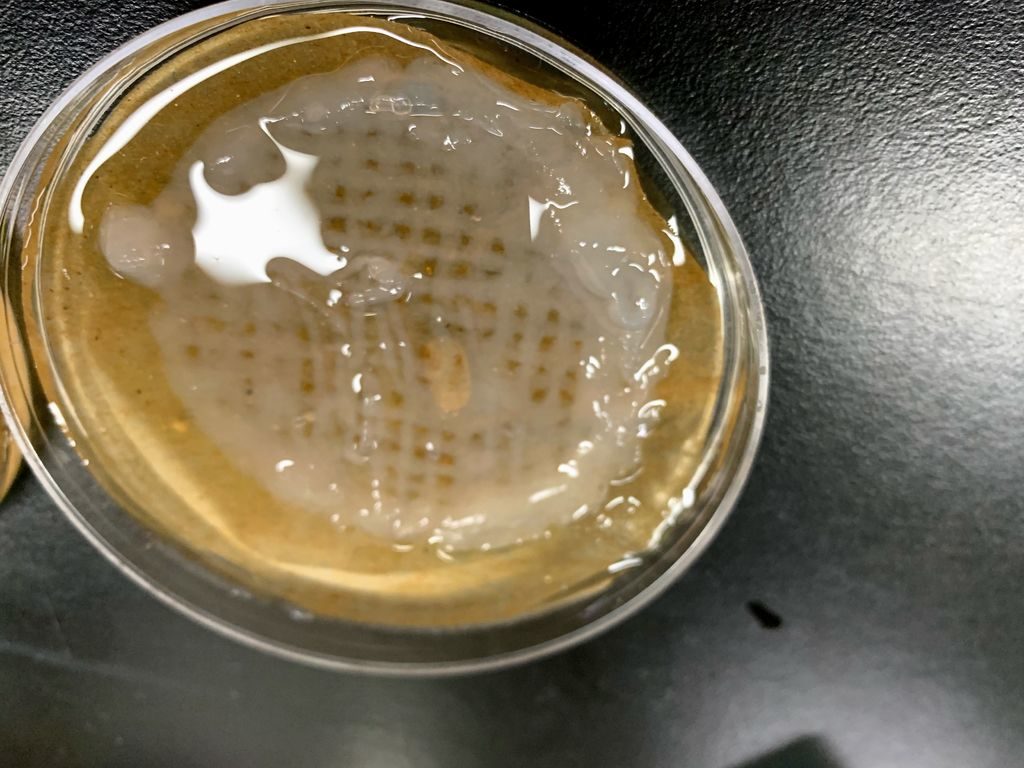

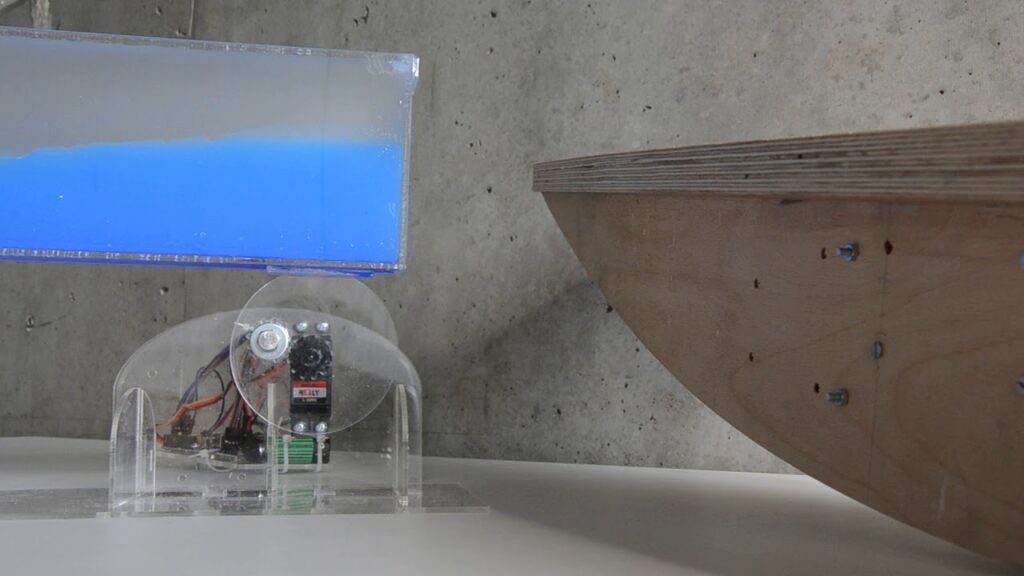

The device features two parts — an oil/water wave diorama which sloshes around using a servo actuator and a wooden “surfboard” large enough for a person to stand on.

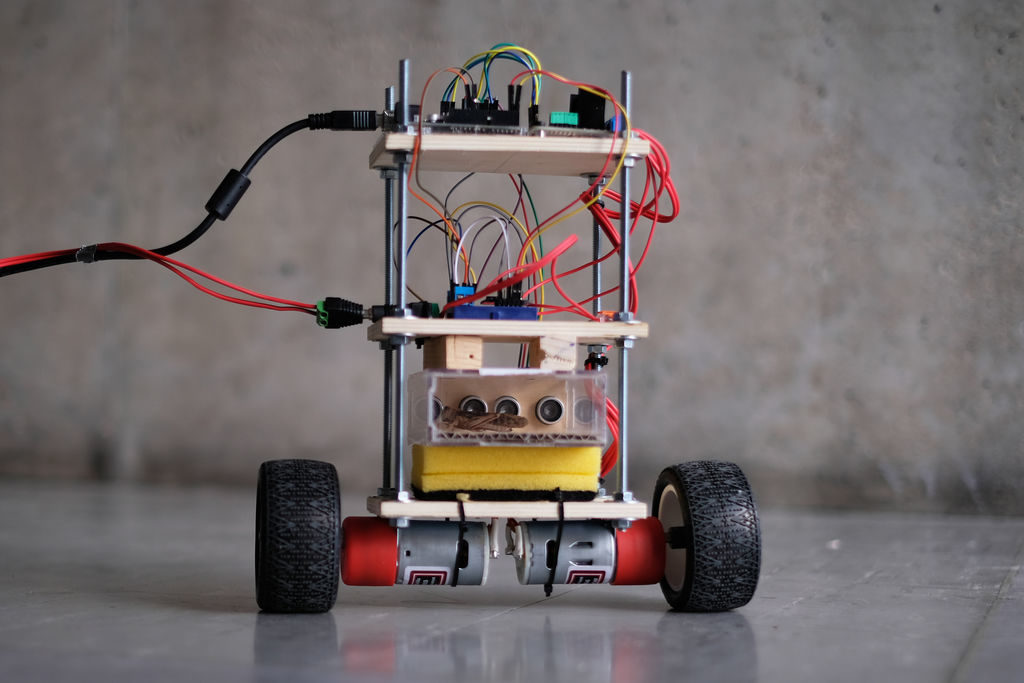

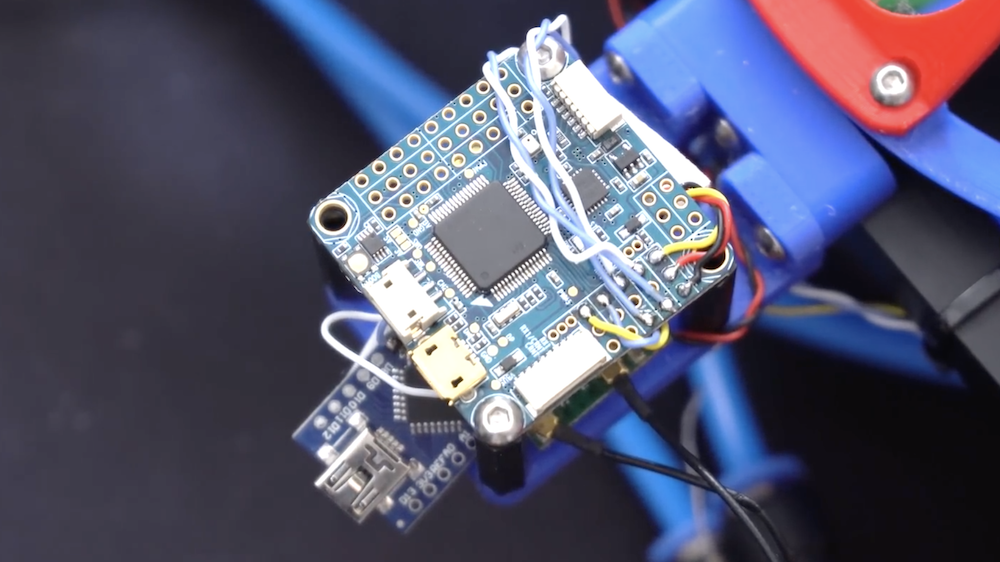

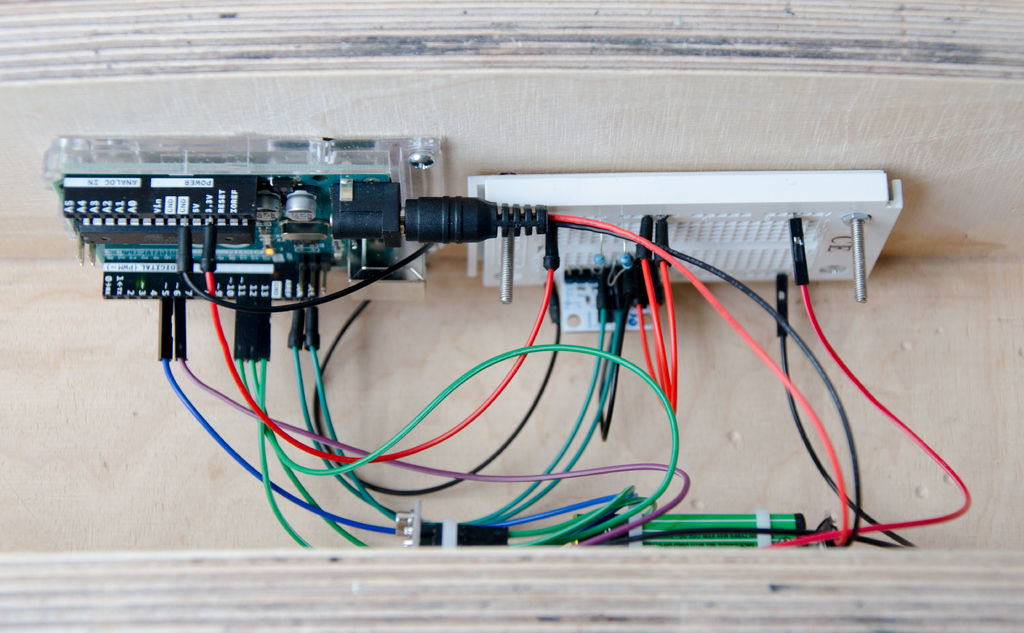

The board is curved on the bottom enabling for someone to tilt it back and forth with their body movement, while a three-axis accelerometer handles angle measurement. This data is then passed from an onboard Arduino Uno to a second Uno that drives the diorama’s servo via nRF24L01 radio transceivers.

The result is an actual body-controlled wave motion, and a distraction that looks like a lot more fun than simply pushing a tank around with your finger!

Do you feel a sudden urge of going surfing, but there is no large body of water nearby? Are you scared of deep and turbulent waters? Or are you just to lazy to go outside? Then the Ultra Realistic Surfing Simulator is the perfect solution for you! It allows for a close to reality surfing experience from any place imaginable. As a two part system, motion is sensed by a board and translated into wave motions of an ocean diorama.