The Santa Cruz Robotics Club met again today, for the first time in over a month. The current project is not the underwater ROV (we’re all getting very tired of waterproofing problems), but an automated Nerf gun.

The club members came up with some very ambitious plans for the Nerf gun (which included getting a Raspberry Pi and doing image processing to have a self-aiming gun), but I’m making them build quick-and-easy prototypes to try out their ideas one step at a time. I don’t think I can get an Raspberry Pi this summer—the companies doing the distribution aren’t taking more orders (just expressions of interest) and they don’t expect to clear the current backlog until September at the soonest. They are doing batches of 100,000 units, and that doesn’t seem to be enough to shrink the lead time—if anything, the lead time is growing.

So, giving up on image processing for this summer, there are still a lot of things to build. For today’s four-hour meeting (which included a 1-hour trip to the hardware store and a fifteen-minute snack break), the goal was simply to test out the basic launcher concept: an air reservoir pressurized by a bike pump, a solenoid valve, and a barrel.

The first prototype. The air reservoir is about 18″ of 1-½” PVC pipe on the left, and the barrel is about 24″ of ½” PVC pipe on the right.

The biggest problem was that the valve has ¾” male pipe threads, but we wanted 1-½” PVC pipe for the reservoir (because we had a piece handy—we may build a bigger reservoir later) and ½” PVC pipe for the barrel (because Nerf darts just fit inside—probably Nerf guns were prototyped with PVC barrels). Our hardware store run was to get threaded adapters to make things fit.We wanted everything to be joined with screw threads, so that we could disassemble the components and replace them or add elbows as needed.

Note that the ½” PVC pipe is also a good size for compressed-air paper “rockets”. The term “rocket” is a misnomer here, as all the acceleration occurs while the rocket is on the launcher—it is modeled more like a gun than like a rocket. (But my soda-bottle rocket simulator can model these paper bullets also.) It would probably best to have a shorter barrel for doing rocket launching—just the length of the rocket and no more, since the longer barrel results in more pressure loss with no gain in launch speed.

The bicycle valve glued into a ½” female-threaded end cap was one I’ve had for a long time, as part of a soda-bottle rocket launcher. I had two of them, and both failed in testing today (the Barge cement holding the valve stem in failed—we’ve now reglued them with a different cement), though we managed some testing before the failure.

The solenoid valve we used was the same model (sold by Sparkfun) as the one used for the vacuum bottle on the ROV. It has ¾” male pipe threads on each side. To make it air-tight we had to disassemble it and grease the rubber membrane thoroughly with vaseline or faucet grease, but we had done that months ago, so it did not need to be done today. The valve only works in one direction, but the high-pressure side is clearly marked by a metal intake screen, so assembling it the right way around is easy.

I was not sure that the solenoid valve would work in this application. It is not the model of valve that the compressed-air “rocket” people have used—those valves cost about twice as much and have female threaded ends rather than male threaded ends. I think that the mechanism they use may open up a bigger channel for air or water than the cheap solenoid valve sold by Sparkfun.

My first concern was that I did not know whether the valve would open up wide enough and fast enough to let a blast of air through to get a clean launch. Second, I did not know whether we could open and close the valve fast enough to retain pressure in the reservoir for doing multiple shots.

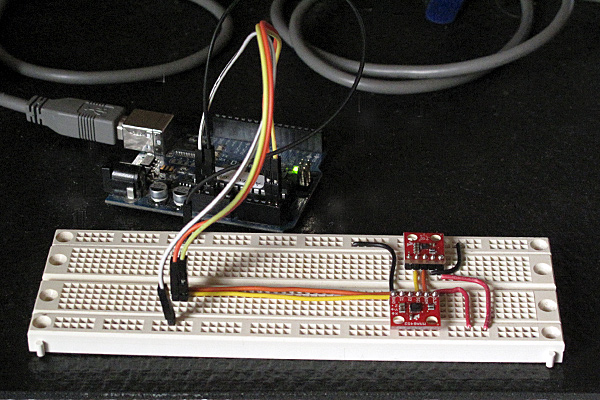

We controlled the solenoid valve with an Arduino and the Hexmotor motor-control board (which is really overkill for one solenoid—a single power transistor would be enough to interface the Arduino to a solenoid, but I did not have one handy). My son wrote an Arduino program to allow us to experiment with the duration of the solenoid pulse. If it were too short, the Nerf dart would not leave the barrel. If it were too long, air pressure would be wasted. He allowed for 100 µsec increments in pulse duration, under control from commands on the USB serial line.

Because the glue they used takes 24 hours to set properly, we only tested at low pressure today (20–30 psi). At those pressures, a 16 msec pulse was not long enough for the dart to clear the barrel, but a 19.2 msec pulse was easily long enough. We were also able to launch a 14g paper “rocket” left over from Maker Faire, though it did not go as high as the approximately 1.6g “Nerf” darts (I think several of the foam darts we have a different brand). We would not have expected it to go as high, since it was only accelerated for its 11″ length, not the 24″ length of the barrel for the darts, and it weighed a lot more.

One thing I thought about was monitoring the air pressure in the reservoir electronically. I doubt that we’ll put a pressure sensor in the reservoir, though, as the sensors I have only go up to 250 kPa absolute (about 21 psi above atmospheric pressure—about as low as we could fire with). Freescale makes a 145psi (1000 kPa) sensor, the MPX5999D, but it is a differential sensor without port tubes (so would be difficult to mount) and it costs $13.

Perhaps the other thing worth doing today is to analyze how fast the Nerf dart should be going as it leaves the barrel, and how high it should fly if we shoot it straight up. The physics here is fairly simple, if we assume that opening the solenoid valves connects us to a constant-pressure source. (In practice, we saw about a 10psi or 70kPa drop in pressure after one shot. If the pressure is P, then the force on the dart is P*area. The cross-sectional area of the foam dart is a little hard to measure, because of the squishiness of the foam, but the inside diameter of the barrel is 1.45cm, for a cross-sectional area of 1.65 cm^2. At 140 kPa (about 20 psi), the force on the dart would be 23 Newtons. That force is applied for about 60 cm (the length of the barrel), for a total energy of about 14 Joules.

We can use the kinetic energy of the dart to get its speed (E = ½ m v2), so for 140 kPa, the dart should leave the barrel at about 130 m/s or 290 mph. I suspect that we are not getting anywhere near that speed, for several reasons, including leakage of air around the dart, limited speed of air moving through the valve, and friction of the dart in the barrel (mainly from the pressure wave in front of it, but also from rubbing on the sides of the barrel).

We can also use the kinetic energy of the dart to estimate how high it would fly (ignoring air resistance, which is obviously hugely important for a low density object like a foam dart). The potential energy of a mass at height h is  , so the height it would go without air resistance is

, so the height it would go without air resistance is  . For 14 Joules and 1.6 grams, that would be almost 900m. I think that 20m is a more reasonable estimate for the height the dart went, though I never could see it near the top of its trajectory.

. For 14 Joules and 1.6 grams, that would be almost 900m. I think that 20m is a more reasonable estimate for the height the dart went, though I never could see it near the top of its trajectory.

I tried adding the specs for the Nerf dart and a 60cm barrel to my rocket simulator (to get a crude estimate of the effect of air drag), and for 140 kPa I got an estimated max speed of 132m/s and an estimated max height of 52.6m. I don’t know if that height is reasonable—certainly it is better than the no-air-resistance estimate. The 6.78 second estimated time of flight seems to be fairly reasonable, though we never timed it.

Doubling the pressure increases the maximum velocity by a factor of 1.414, but only increases the maximum height to 60.8 m, a 16% increase. Doubling the barrel length has about the same effect. Air drag is what determines the speed of the dart, and that is the least well-modeled part of my simulation.

On Thursday, when they club meets again, they’ll try experimenting with higher pressures, and see whether 17 or 18 msec pulses are long enough—the shorter the pulse the less air will be wasted, and the more shots they can make from the reservoir. It may be necessary to design a bigger reservoir or add a compressor to the design, since they eventually want a fully automatic Nerf gun, not the one-shot muzzle-loader that they made as the prototype today. They’ll also start designing a pan-tilt mechanism for the Nerf gun, probably prototyping it out of Lego Technic components.

Filed under:

Robotics Tagged:

Arduino,

Nerf gun,

nerf guns,

physics,

rocket,

simulation,

SparkFun Electronics