Motorize a manual standing desk

Martin Mihálek took the leap into standing desks, and purchased a SKARSTA table from IKEA. Although being able to adjust things by hand is useful, who wants to do that nowadays? Instead of manually cranking it every time, he—with help from iLLiac4—decided to augment it with a motor in order to lower and raise things as needed.

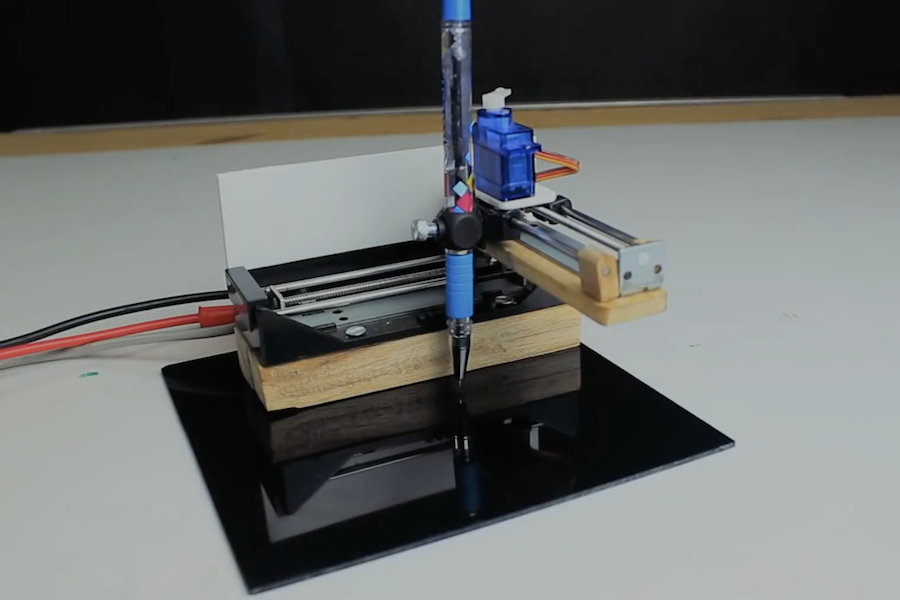

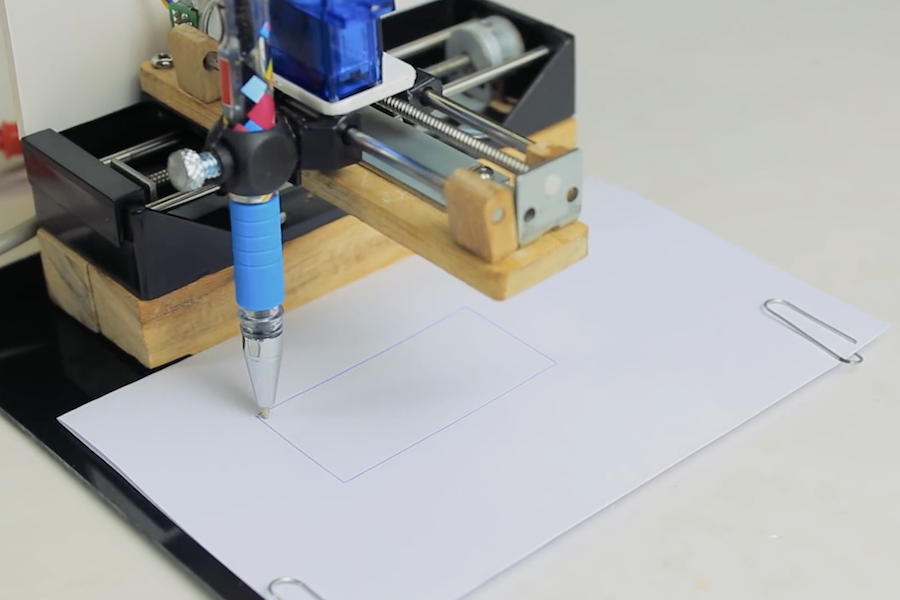

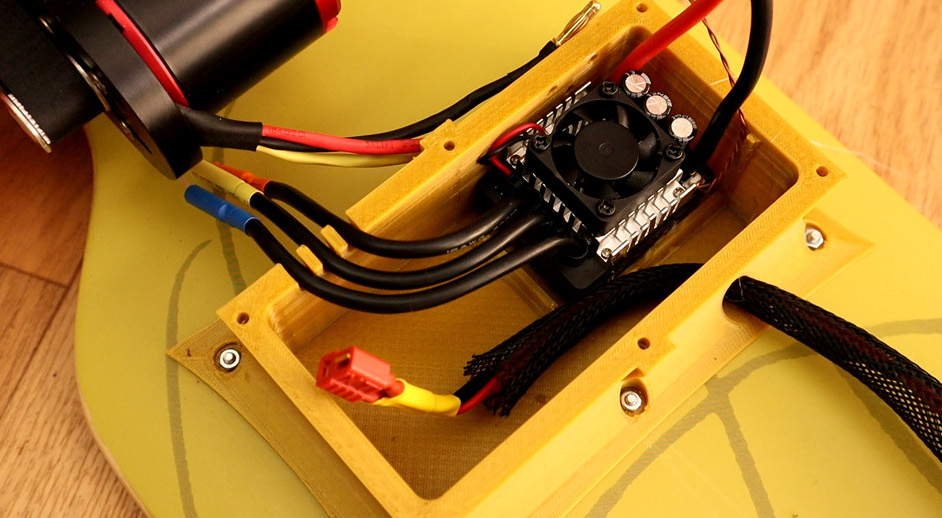

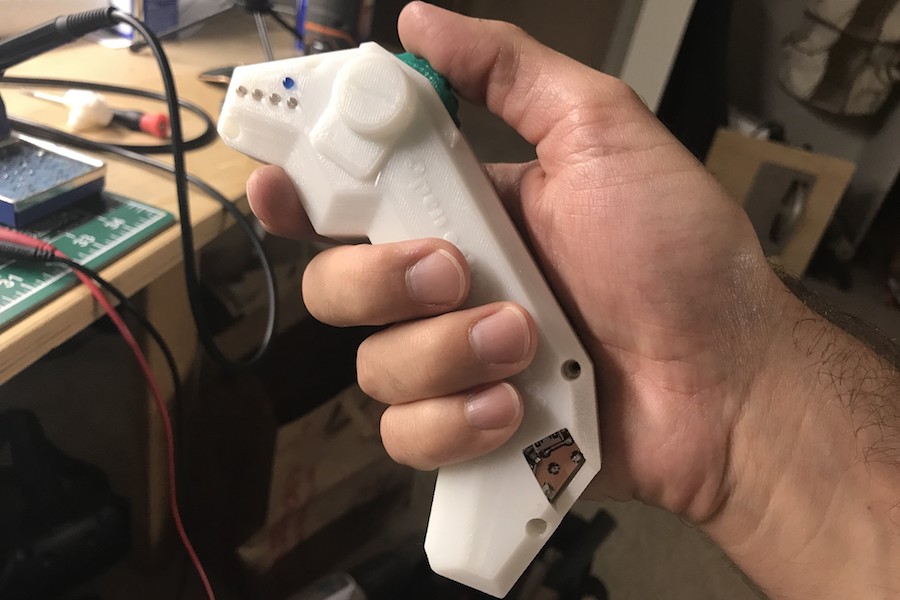

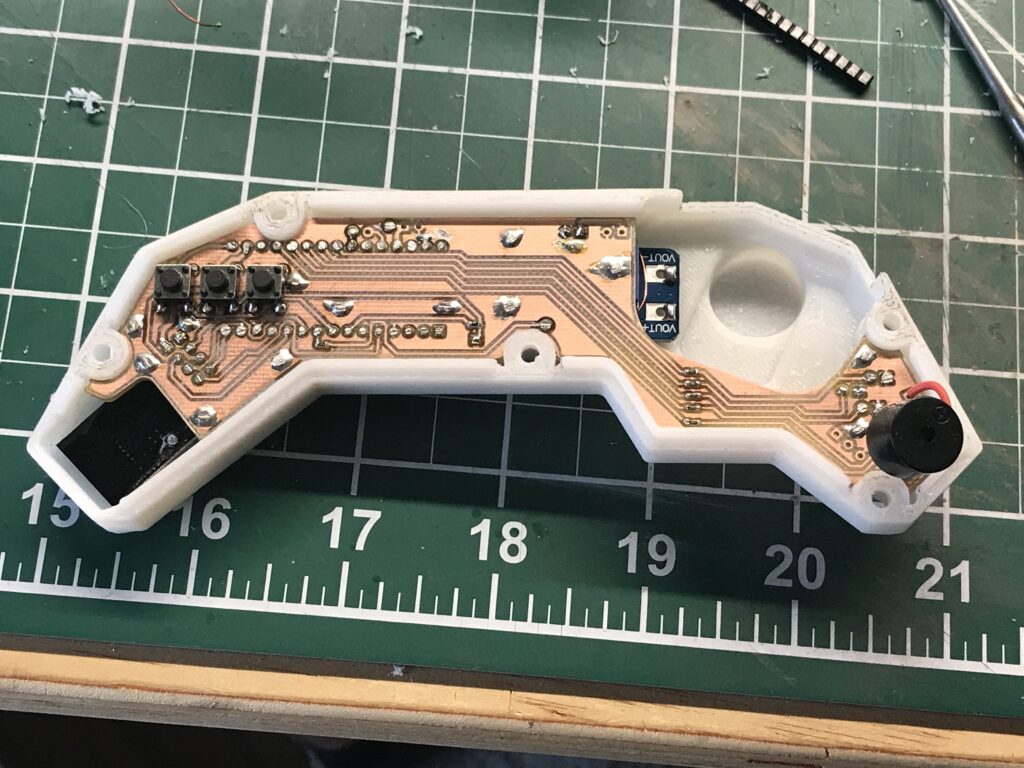

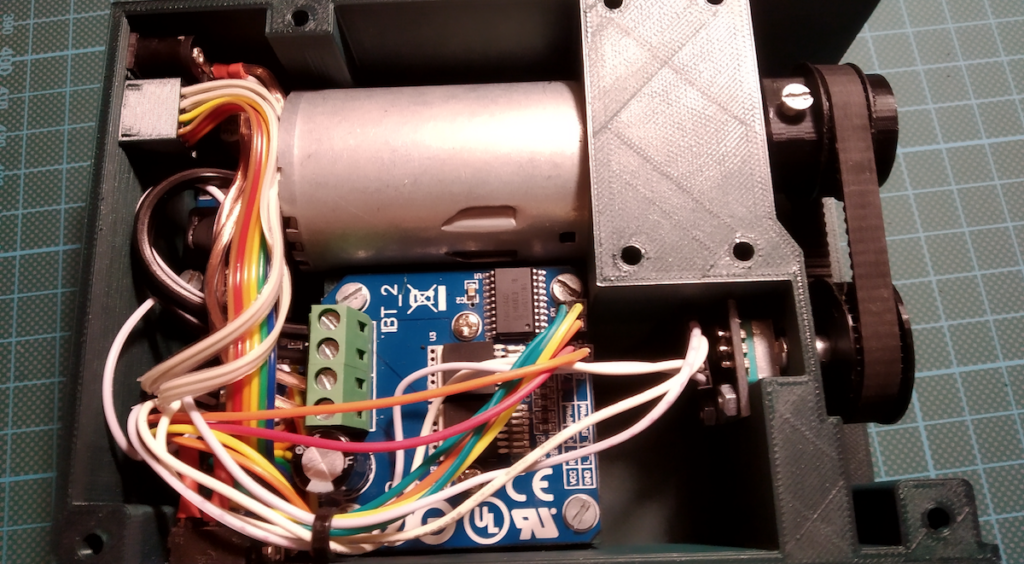

Initial experiments used a FIXA electric screwdriver (also from IKEA) to power the SKARSTA, but he eventually settled on a DC gearmotor, attached to the desk via a 3D-printed assembly.

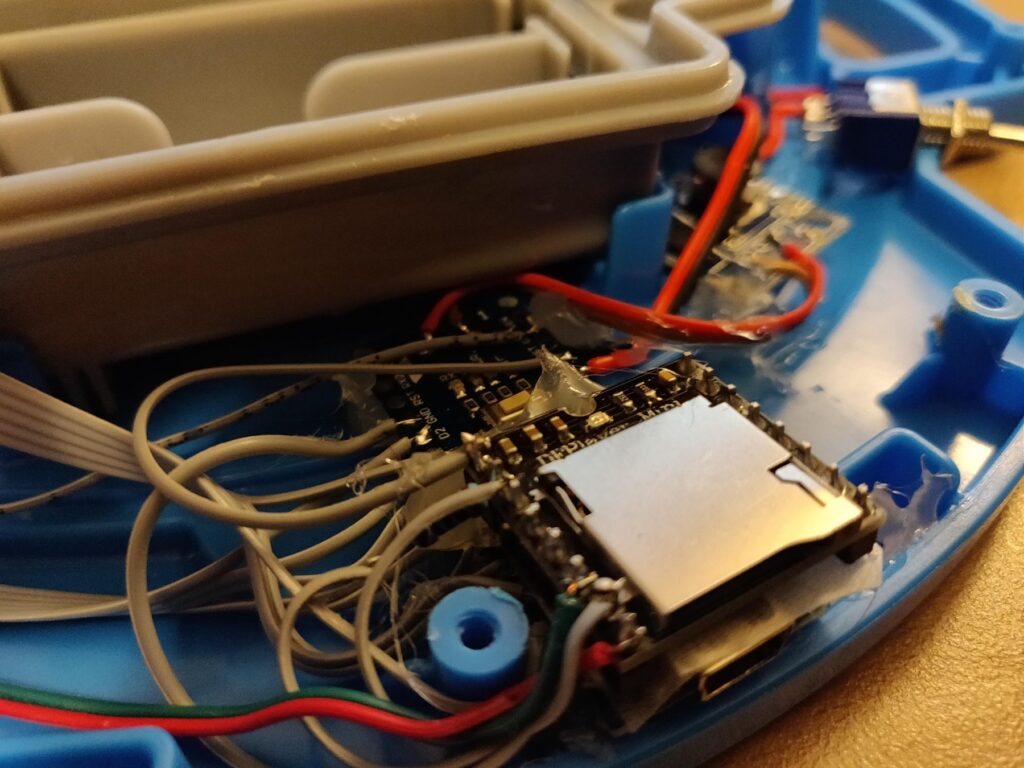

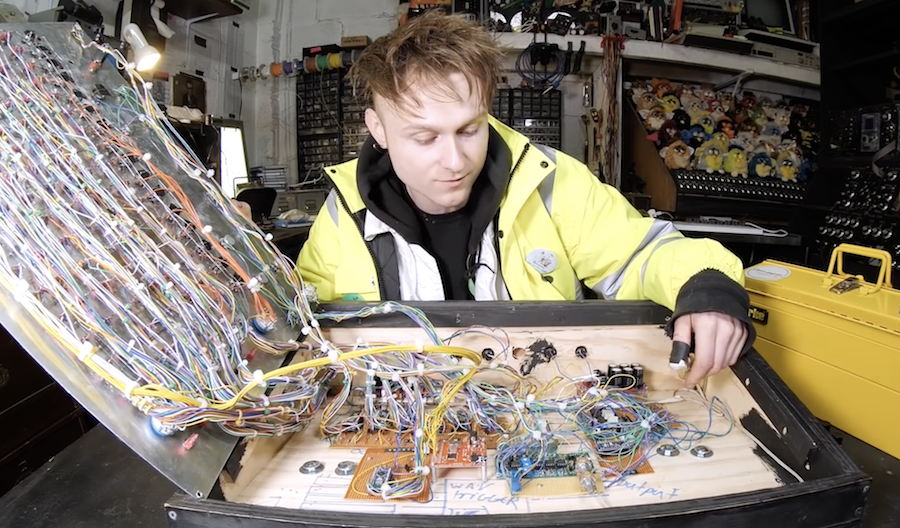

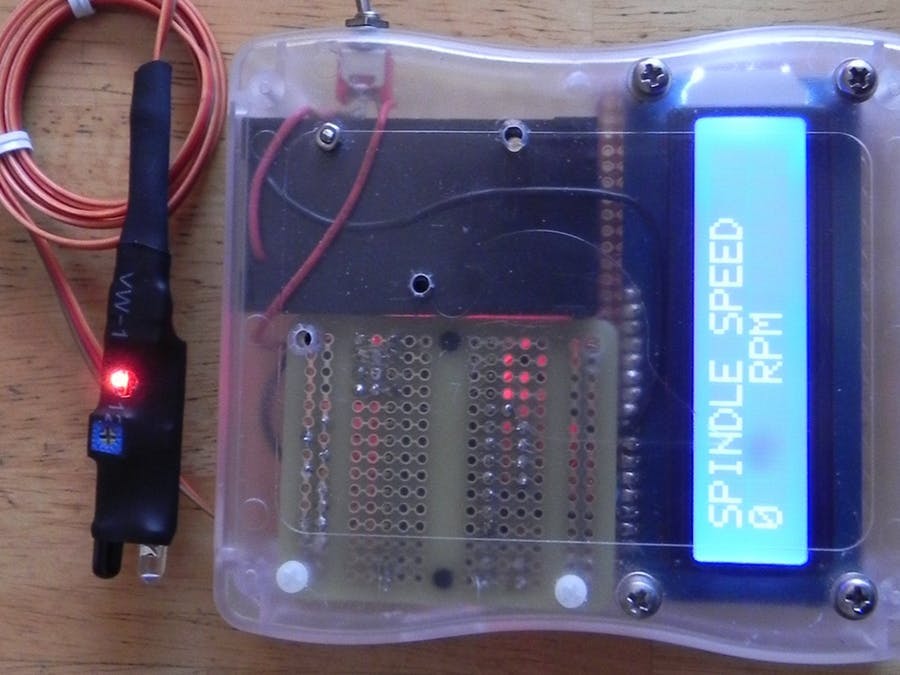

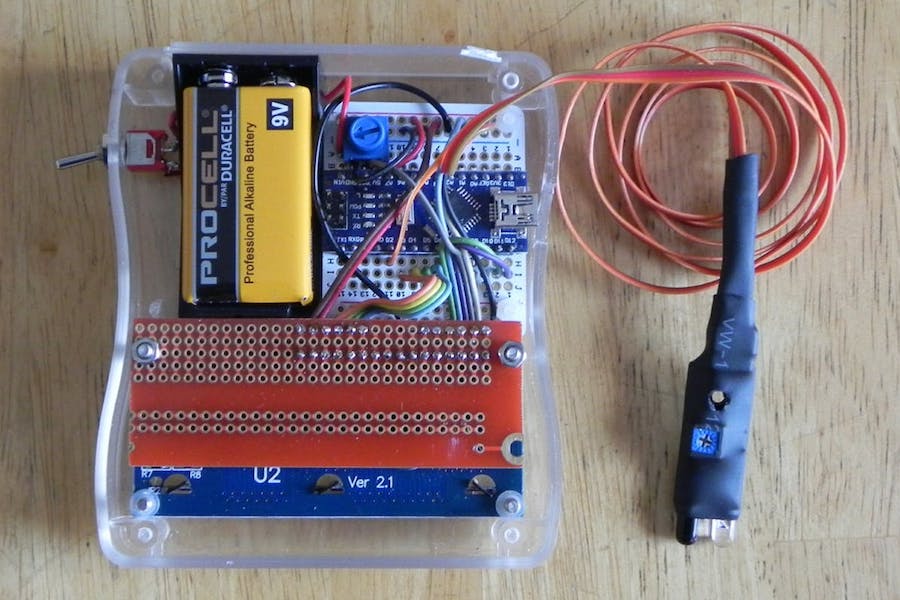

Two versions are described in the project’s GitHub write-up; one employs an H-bridge board for control, the other uses relays. Both are controlled by an Arduino Nano. A keypad allows for calibration and three stored heights, while current position and feedback are shown on a TM1637 4-digit 7-segment display.