Pen Plotter From Salvaged Printer Parts

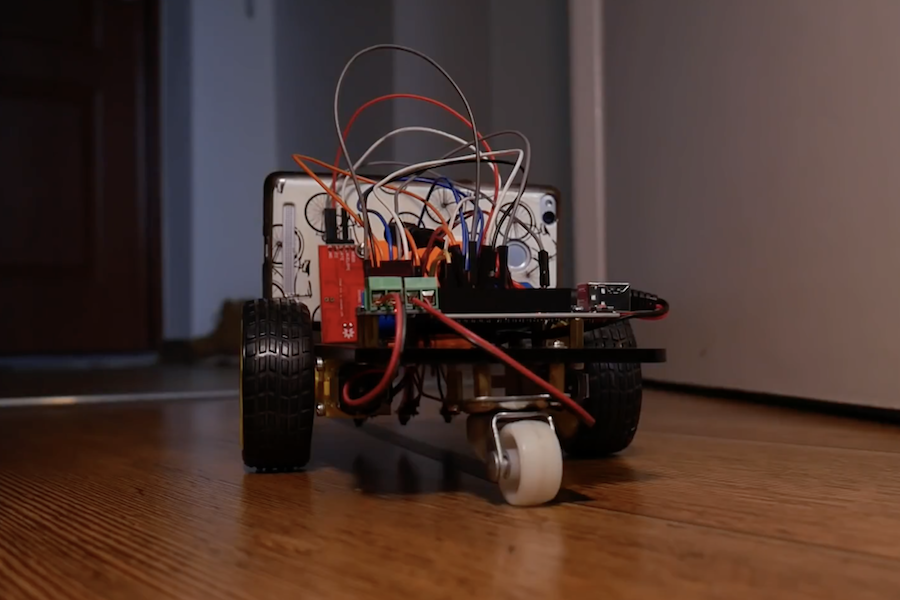

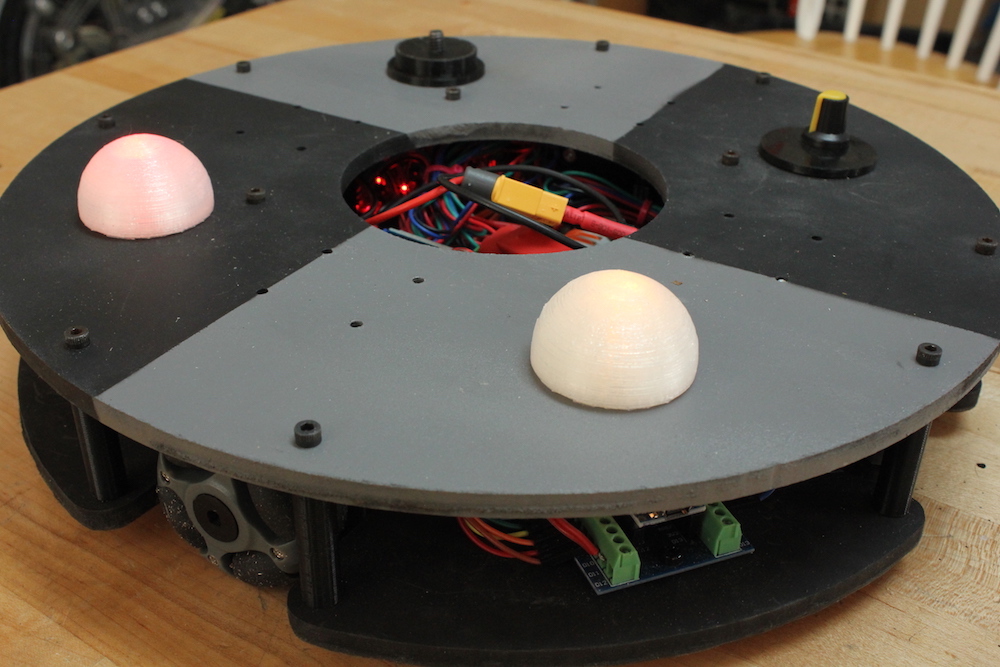

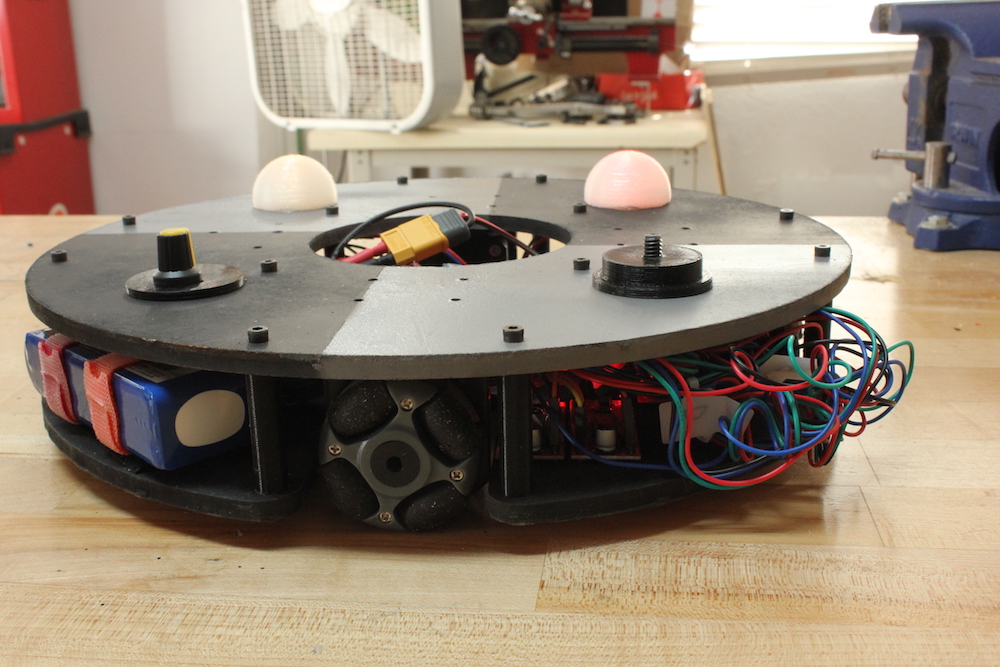

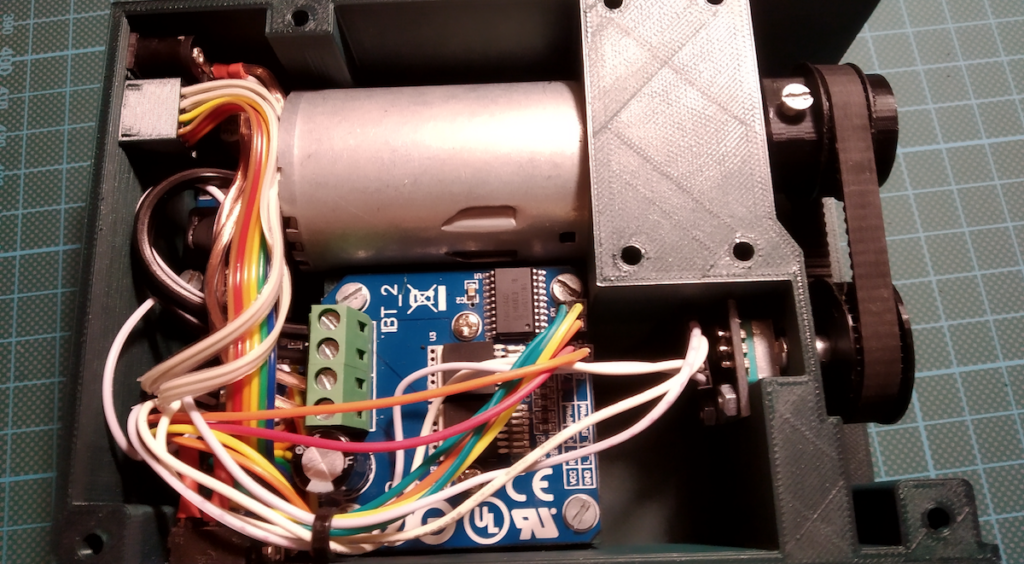

Like many of us, [Benjamin Poilve] was fascinated when he took apart a broken printer. He kept the parts, but unlike most of us, he did something with them, building a neat little plotter called the Liplo. Most pen plotters work by moving the pen on two axes, but [Benjamin] took a different approach, using the friction drive bars from the printer to move the paper on one axis, and a servo to move the pen on the other. He’s refined the design from its initial rough state to create a very refined final product that uses a combination of salvaged, 3D-printed, and CNC-milled parts.

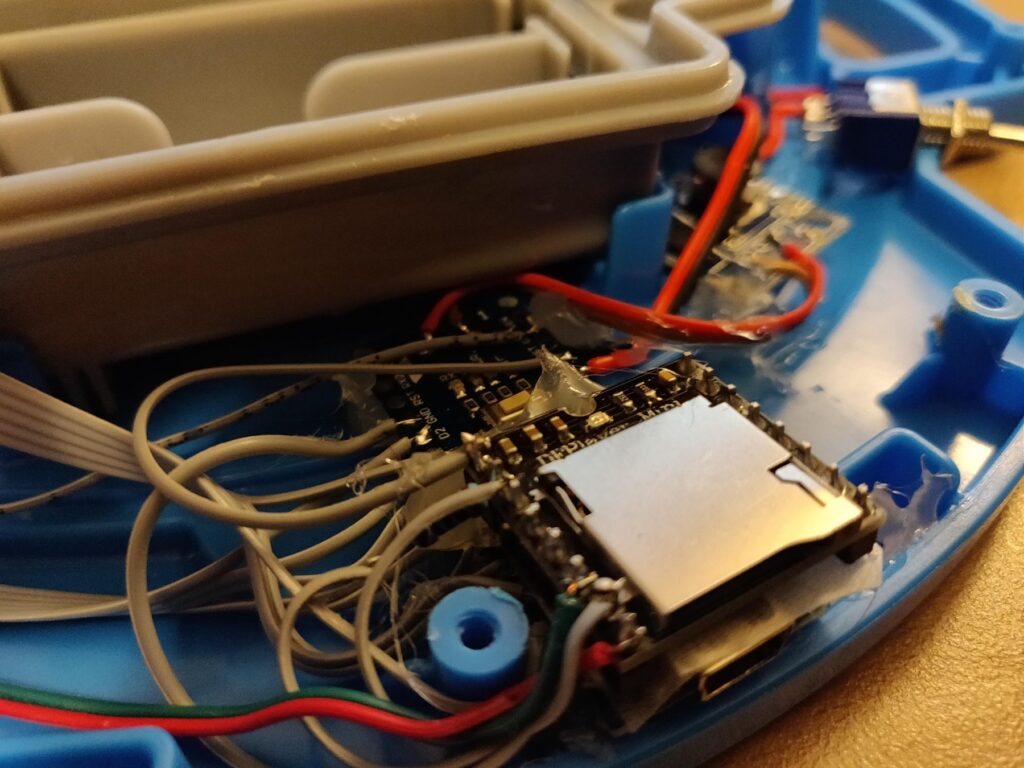

The Liplo is driven by a Teensy 3.1 and an Eibot board to drive the motors. [Benjamin] was planning to offer the plotter a kit on Kickstarter, but life got in the way. His loss is our gain, as he is now offering the plans and code for this neat build for free. If this one doesn’t plot your desires, we’ve seen lots of other home built plotters recently, including this one made from a 3D printer, and even one made of cardboard.