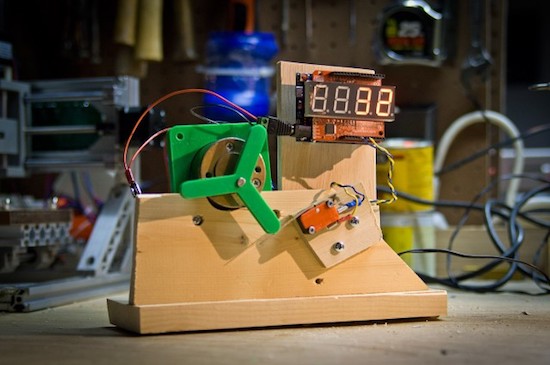

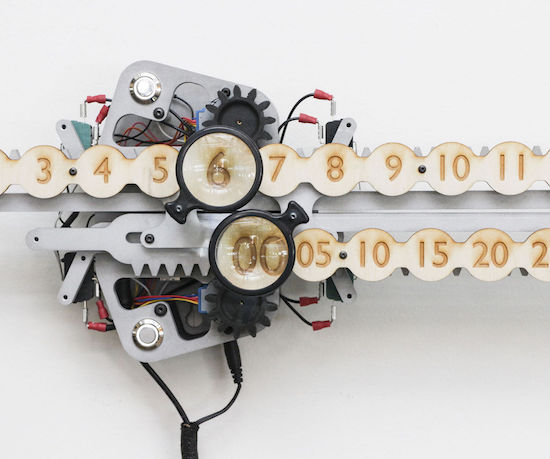

Geared clock measures time linearly

Jonathan Odom, a full-time designer at Instructables who goes by the name “JON-A-TRON,” decided to make a clock illustrating time’s linearity. What he came up with was a beautifully crafted (robotically manufactured at the Pier 9 workshop, that is) clock that uses two rack and pinion assemblies to move a line of numbers for hours on top of another line signifying minutes.

The minute “hand” is divided up into five-minute intervals, which seems to him to feel less neurotic than being precise down to the exact minute. Magnifying glasses are used to magnify an hour and minute number, reminding onlookers to focus on the present.

The clock is actuated using an Arduino Uno with a motor driver, controlling a stepper motor for each “hand.” It’s an incredible build, and nicely illustrated. Whether or not you have access to the tools needed to recreate this exact clock, perhaps this concept will inspire something similar!

Be sure to check out Odom’s clock Instructables write-up here and see a demo of it below!