A wireless monitoring solution for solar power systems in remote locations

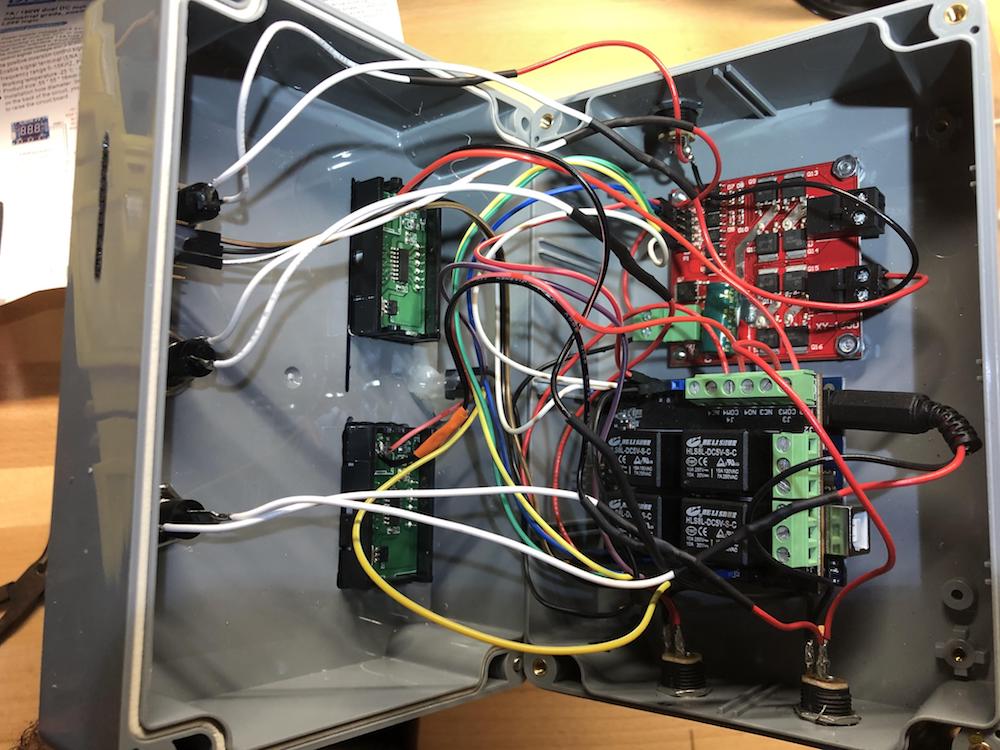

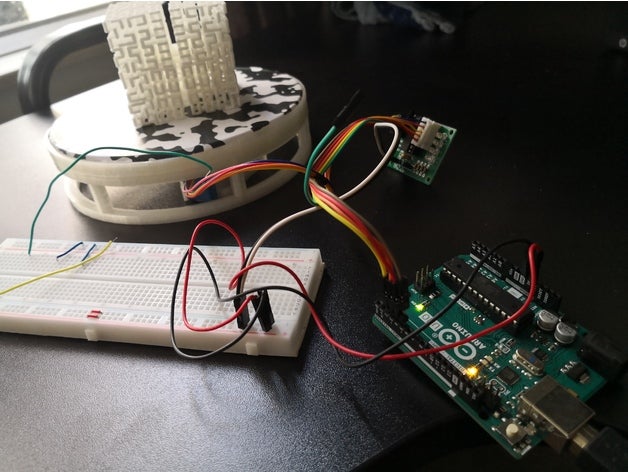

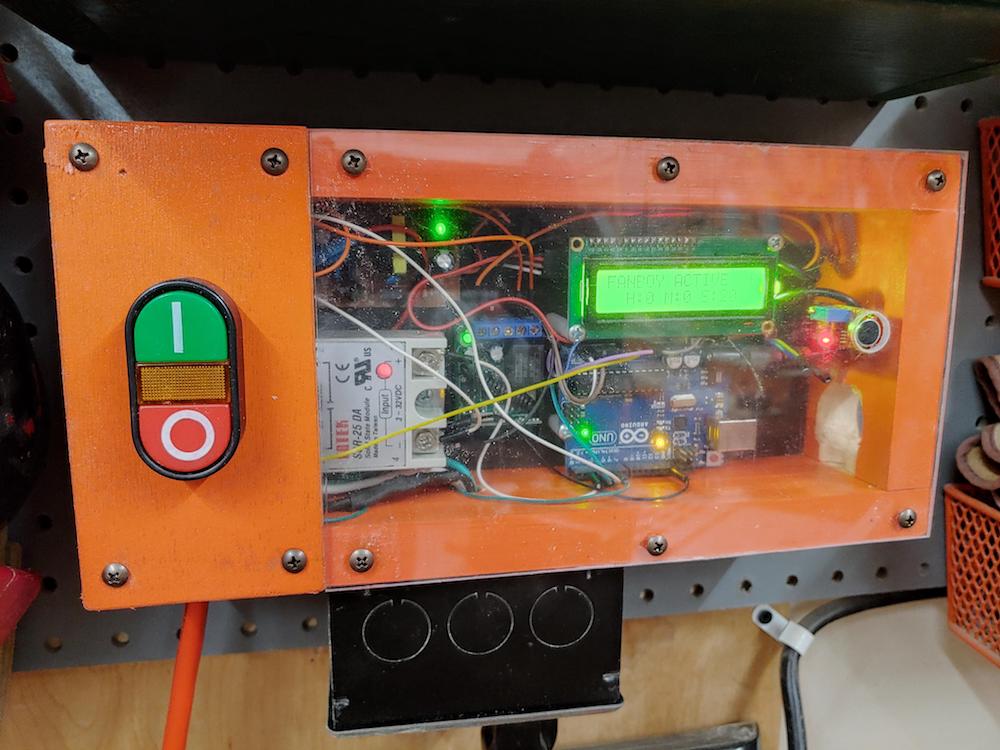

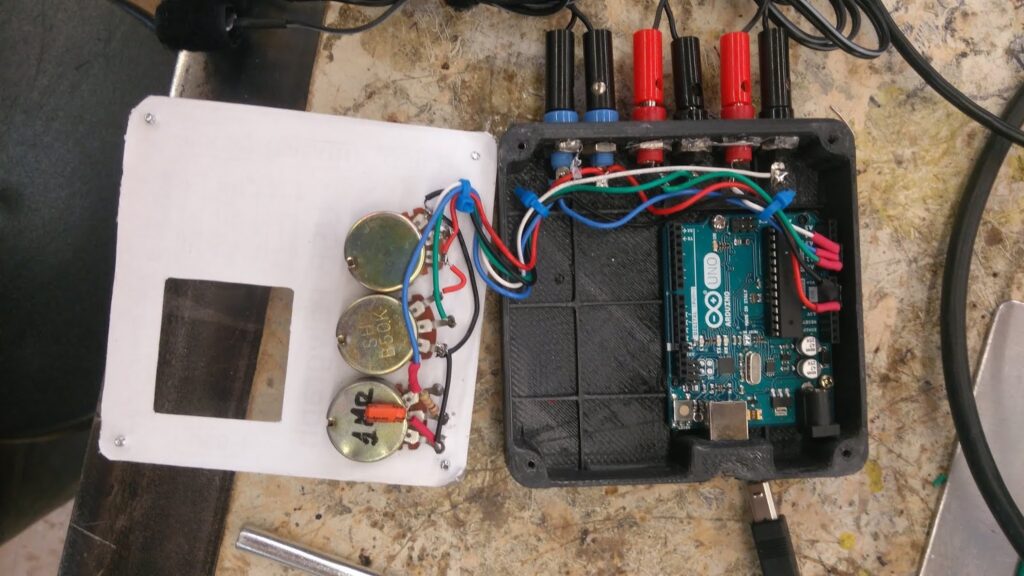

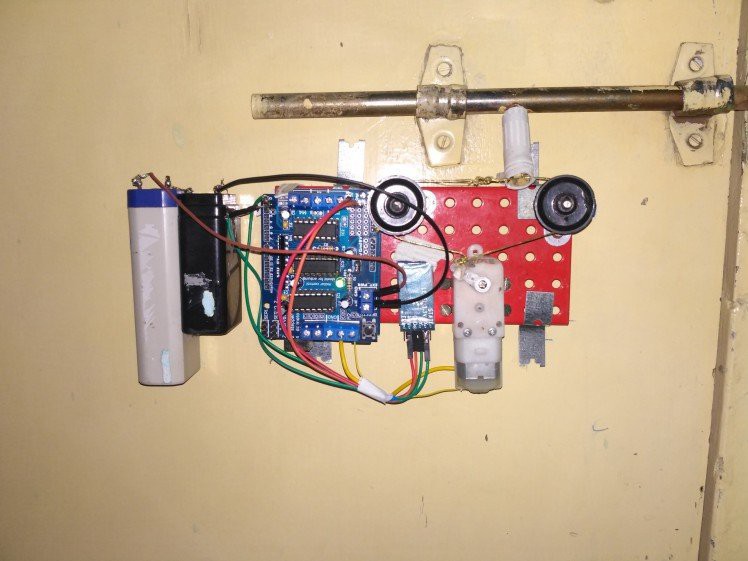

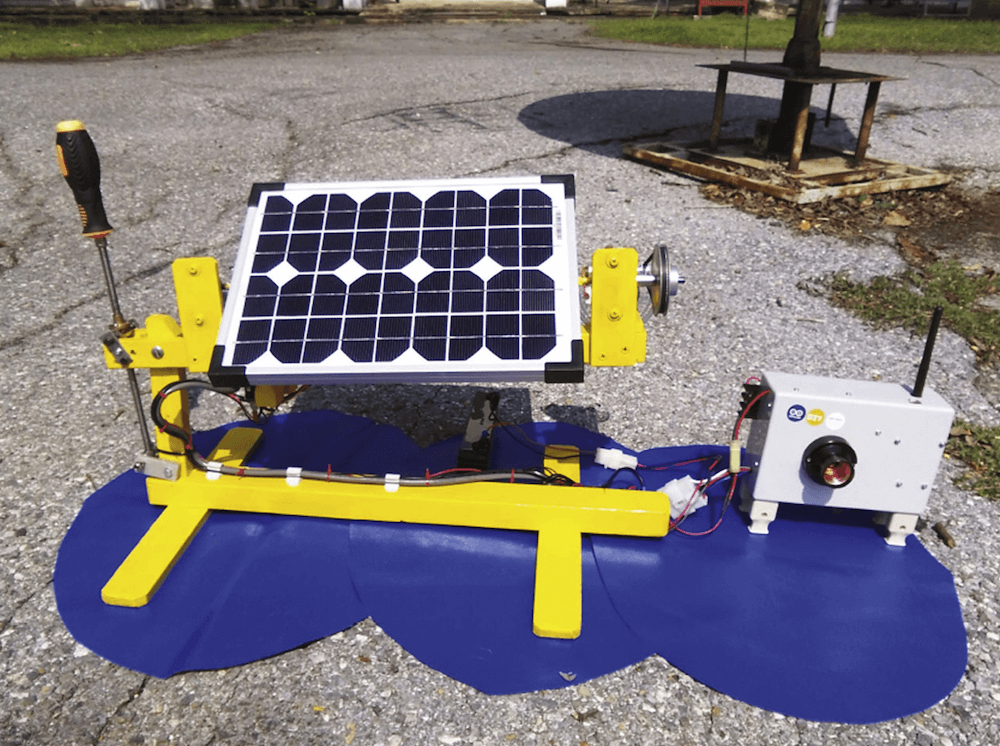

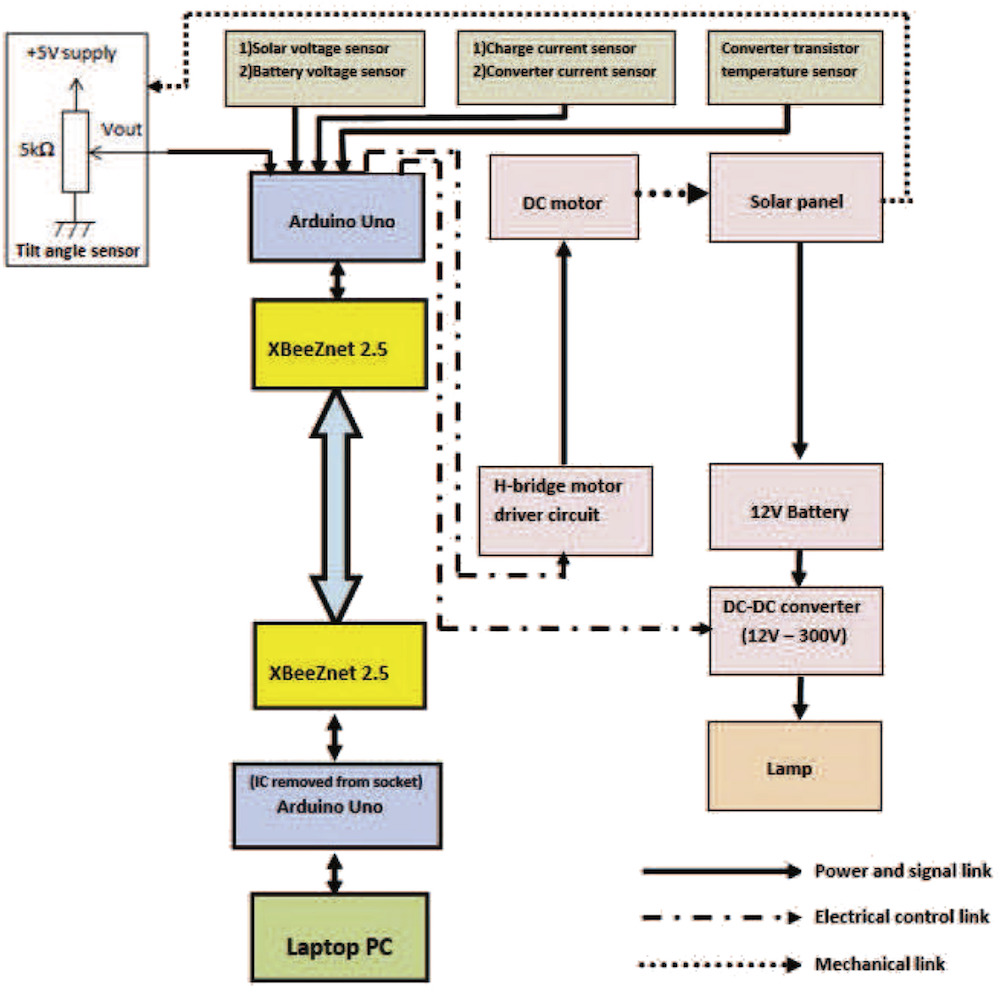

Researchers in Thailand have developed a ZigBee-based wireless monitoring solution for off-grid PV installations capable of tracking the sun across the sky, tilting the panel hourly. The elevation for the setup is adjusted manually once per month for optimum energy collection. The prototype is controlled by a local Arduino Uno board, along an H-bridge motor driver to actuate the motor and a 12V battery that’s charged entirely by solar power.

The system features a half-dozen sensors for measuring battery terminal voltage, solar voltage, solar current, current to the DC-DC converter, the temperature of the power transistor of DC-DC converter, and the tilt angle of solar panels according to the voltage across the potentiometer.

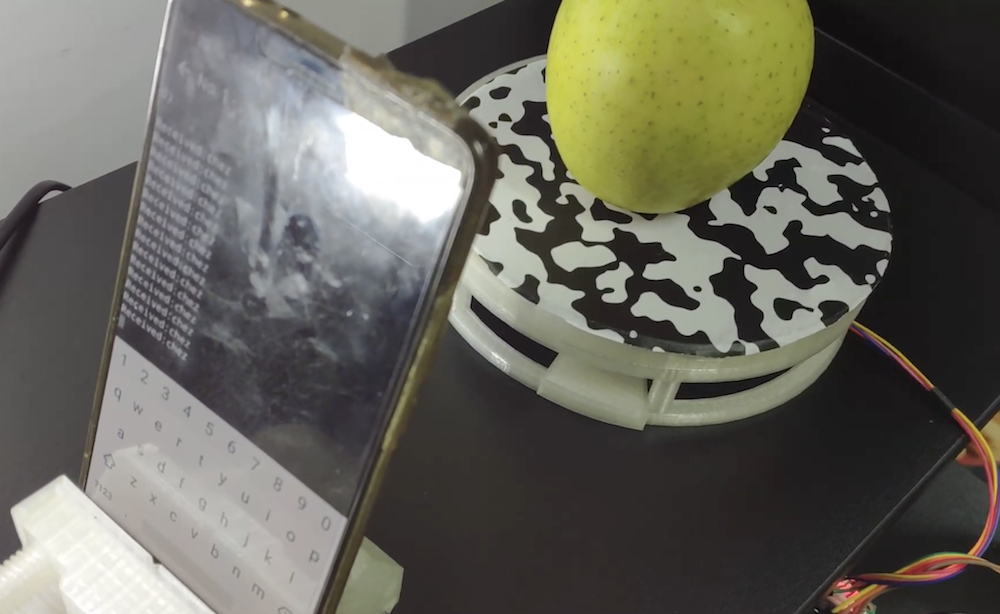

Data is transmitted wirelessly via an XBee ZNet 2.5 module to a remote Uno with an XBee shield. The real-time information is then passed on to and analyzed by a computer, which is also used to set the system’s time.

More details on the project can be found in the team’s paper.

Wireless sensing is an excellent approach for remotely operated solar power system. Not only being able to get the sensor data, such as voltage, current, and temperature, the system can also have a proper control for tracking the Sun and sensing real-time data from a controller. In order to absorb the maximum energy by solar cells, it needs to track the Sun with proper angles. Arduino, H-bridge motor driver circuit, and Direct Current (DC) motor are used to alter the tilt angle of the solar Photovoltaic (PV) panel following the Sun while the azimuth and the elevation angles are fixed at noon. Unlike the traditional way, the tilt rotation is proposed to be stepped hourly. The solar PV panel is tilted in advance of current time to the west to produce more output voltage during an hour. As a result, the system is simple while providing good solar-tracking results and efficient power outputs.