During the summers [Doug] has been building a 75 foot sailing junk to be launched from America’s most inland port. When Oklahoma’s winter hits he heads indoors to work on an ROV that will prowl 3,000 feet below the surface. Originally building a piloted submarine, he grew bored and decided to use the sailboat as a carrier for his fleet of remote submersibles instead.

A consummate amateur, Doug is the first to admit how little he knows about anything and how much he enjoys the open source spirit: collaboration, cooperation and learning from others. Determination and hard work fills in everything in between.

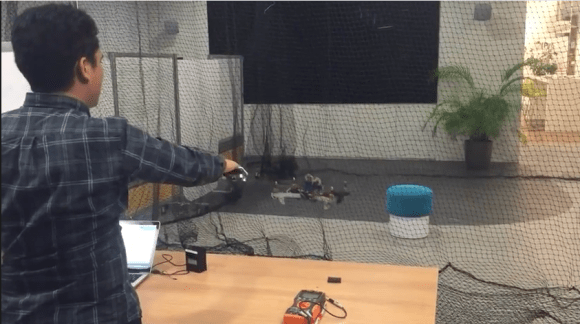

Hackaday covered the beginnings of his ROV last winter. In the year since it has progressed from some sketches and a 10″ steel pipe turned into a pressure testing rig to a nearly-complete, 10 foot long, custom-lathed 4″ aluminum torpedo laying on his shop table. In a bow-to-stern walk-through Doug shows how he is building science equipment for less than a penny on the dollar using largely off-the-shelf imaginatively-repurposed parts or things he could fabricate himself with only a lathe and a 3d printer.

Continue after the break for a breakdown of the tech used.

The body of the ROV alternates between wet (flooded) and dry sections to preserve balance. Surprisingly, the multitude of thrusters on-board are plain RC outrunners most of us would recognize from quadcopters – apparently with a little potting they are not overly harmed by immersion in salt water. Ditto for the LED banks which lack any heat-sinking, relying on exposure to near-freezing seawater for cooling. Dry sections are stuffed full of all manner of gear: a complement of HD IP cameras, RC LiPo (11.1v, 6Ah each) packs, motor ESCs, external & internal pressure sensors, humidity sensors, an inertial measurement unit and relay banks all controlled by an Arduino Mega with an ethernet shield.

The pride and joy of the electronics are an affordable pair of Lowrance sonars for ocean bed mapping, commonly used as fish-finders. He chose the model he did because the board can be collapsed smaller, making it easier to fit into a pressure vessel. Each sonar board is connected to a transducer, one side-scanning and one spotlight facing forward. These display up on the surface what the terrain looks like 150 feet away in the pitch black.

Unexposed wiring having to traverse a between dry sections is handled by brass hose barbs and sealed inside vinyl aquarium tubing. The pressure through the wet section crushes the tubing tight onto the wires. For exposed wiring, [Doug] has come up with own solution of centrifugally packing epoxy into plumbing fittings fitted with connection pins for a 2,600 PSI seal.

The ROV maintains a data connection to the surface with a simple, slightly-buoyant Cat-5e and polycord tether. 5000 feet of cord is too long of a run for household hardware so [Doug] has mounted ordinary Startech VDSL2 extenders which also reduce the wiring requirements down to a single twisted pair (3000 feet yielded 46MBps and only 2ms lag). A bigger issue are the HD cams themselves which they found to be rather jello-like anywhere near HD performance.

When his carrier ship is finished [Doug] plans on sailing around the world, exploring the depths and doing meaningful science into retirement. He figures his $5,000 ROV will match ones sold for $1,200,000. For research projects that puts his open source ROV design in the realm of disposable relative to operations costs. For him it means he is able to own one at all.

All of [Doug]’s videos regarding both his sailing ship (with an ubiquitous $250 schoolbus diesel engine as a backup) and his ROV are superbly filmed, cut and edited. Camera angles change quickly enough to stave off boredom and show both scale and detail of the work. It is easy to spend hours watching how he overcomes each obstacle and budget hurdle.

Ever the collaborator, [Doug] is calling out for anyone who wants to stop by for a visit to work on the boat or to participate in the ROV build with advice. His videos regularly feature collaborators who travelled to help. If you feel you have something to contribute, he seems welcome for assistance.

Filed under:

transportation hacks