I was invited to speak at Tijuana Innovadora, a regional conference/expo. Mark Hatch of TechShop, Jason Short, an industrial designer by day and Drone programmer by night, as well as David Cuartielles of the Arduino team came as well to speak on an open source hardware panel. I must say that crossing the border into Mexico on foot the night before was an unexpected highlight of the trip. (The line leading in the opposite direction was unimaginably long.)

Our host for the event was Guillermo Montoya of Udrones.com, a Mexican company that is owned by 3D Robotics, which is run by Jordi Munoz and Chris Anderson. 3D Robotics is the business side of DIY Drones and sells the arduPilot controller along with planes and quad copters. It has a design and engineering center in San Diego and now does most of its manufacturing is in Tijuana, with plans to move all of it there eventually.

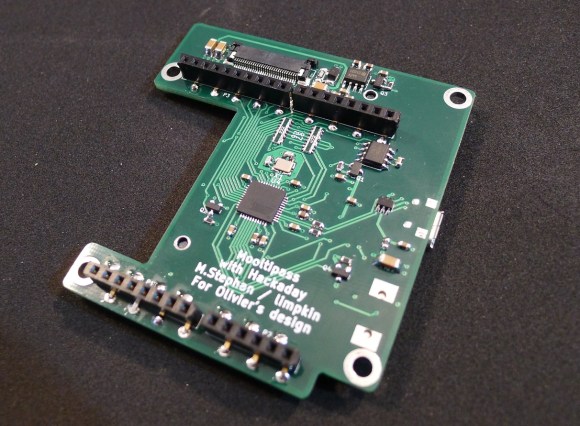

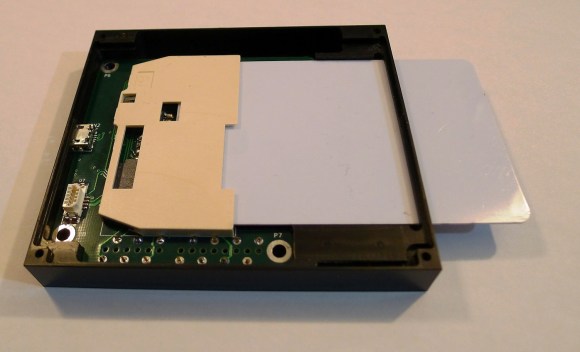

In the evening, after a tasty dinner at a Tijuana cervicheria, we visited the small manufacturing facility of Udrones on the outskirts Guillermo said they had been in the new facility for six months, after starting in his apartment. An electrical engineer, Guillermo is a childhood friend of Jordi Munoz, who is also from Tijuana and talked his friend into starting up this facility. They manufacture ArduPilot boards, cut body parts out on two CNC machines, and then assemble and test the quadcopters and ship them internationally.

The team of Udrones.com (from left to right, above) is Jesus Cain, Manuel Arriaga, Jose Guillermo Romero, Oscar Nunez, and Raul Montoya. Not shown is Lissana Lozano, who helped us find our way around the conference and the city. Raul and Jesus are also students at the university. They said it takes them about a half-hour to assemble a quadcopter.

Jason Short checks out a special black ArduPilot board.

One of the questions that Guillermo asked me was why there weren’t more signs of the maker movement in Spanish-speaking countries, particularly in Central and South America. He noted that there had not been a mini Maker Faire in those regions. There aren’t many hacker spaces either, although at World Maker Faire in NYC I met Tiburcio de la Carcova who had opened a makerspace in Santiago, Chile. I don’t have a good answer for Guillermo. David Cuartielles, who is Spanish, thought that the delays in translating technical information into Spanish is largely responsible. (MAKE is not published in a Spanish edition.) I would like to think that the example of Guillermo and his team might inspire others to see what’s possible.

Filed under:

Arduino,

Design,

Drones,

Open source hardware

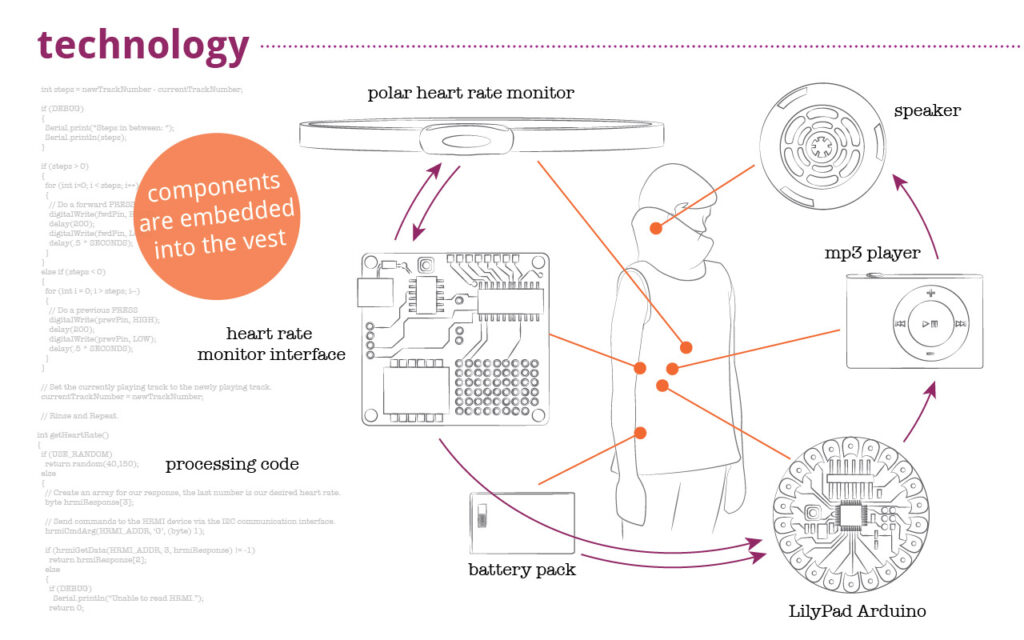

This project is part 4 in the building a robot arm tutorial. In the first part I show how to design the arm, the second part shows how to design the base, and the third shows how to design the mount. After all of the Computer Aided Drafting (CAD) and 3D modeling […]

This project is part 4 in the building a robot arm tutorial. In the first part I show how to design the arm, the second part shows how to design the base, and the third shows how to design the mount. After all of the Computer Aided Drafting (CAD) and 3D modeling […]