Destroyed books tell a unique story

When you pick up a book, the text inside is normally the point, but what if the book itself was the story? That’s the idea behind Alistair Aichison’s Alt.Ctrl.GDC exhibition called “The Book Ritual.”

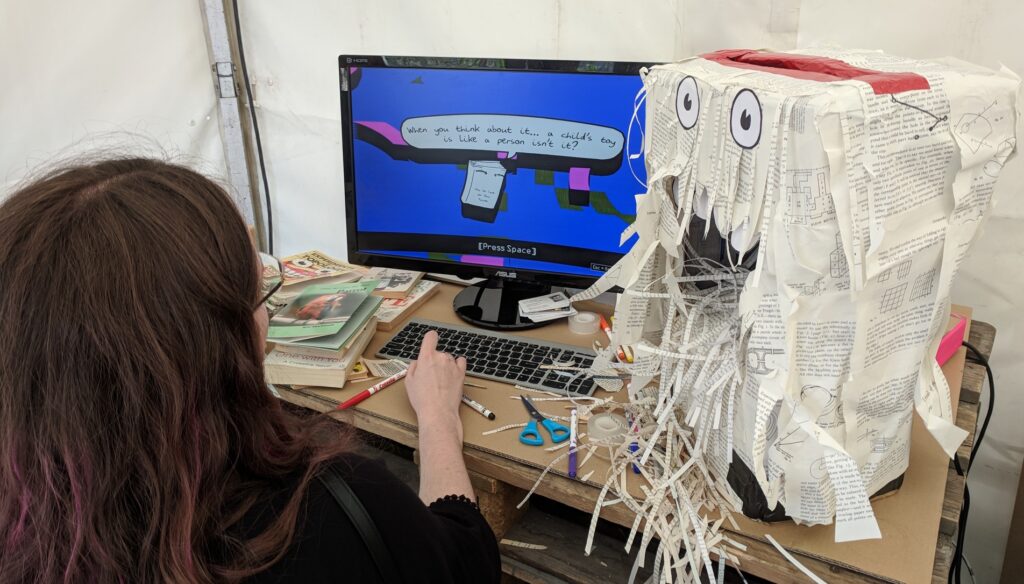

Aichison’s work is told through an interactive computer installation, where an onscreen book talks about loss and change, but also encourages you to add your story by creatively modifying a real book.

The process involves cutting and marking the book, and even requires the user to tear out pages to put it through an actual shredder—this is meant to evoke feelings of loss and regret, ultimately leading to the formation of new memories.

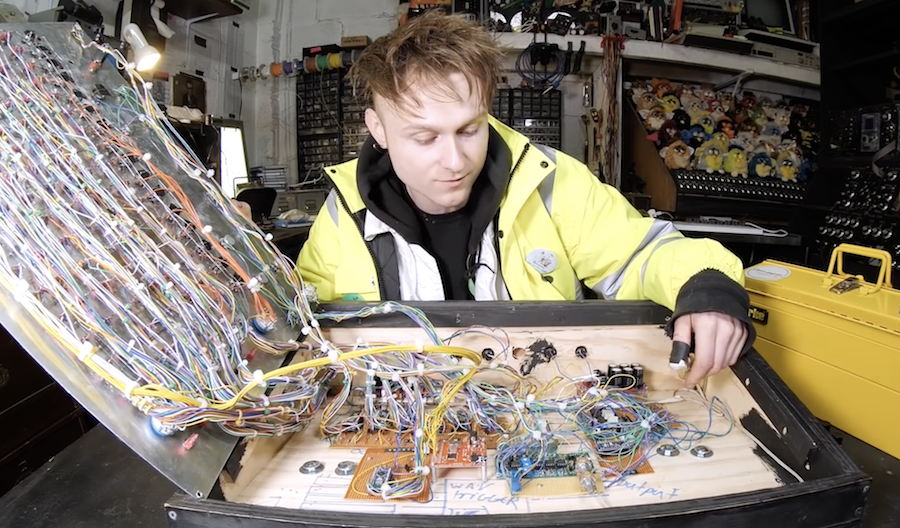

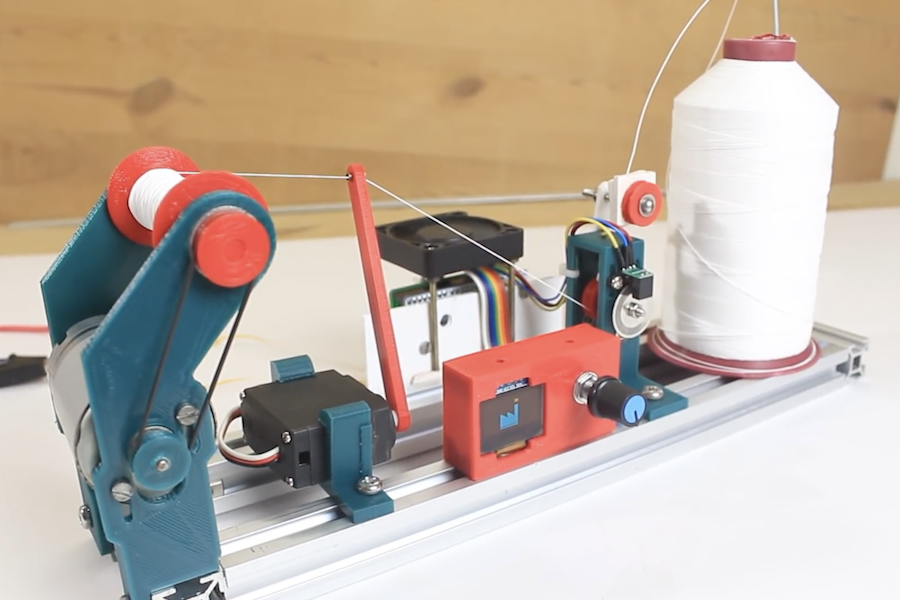

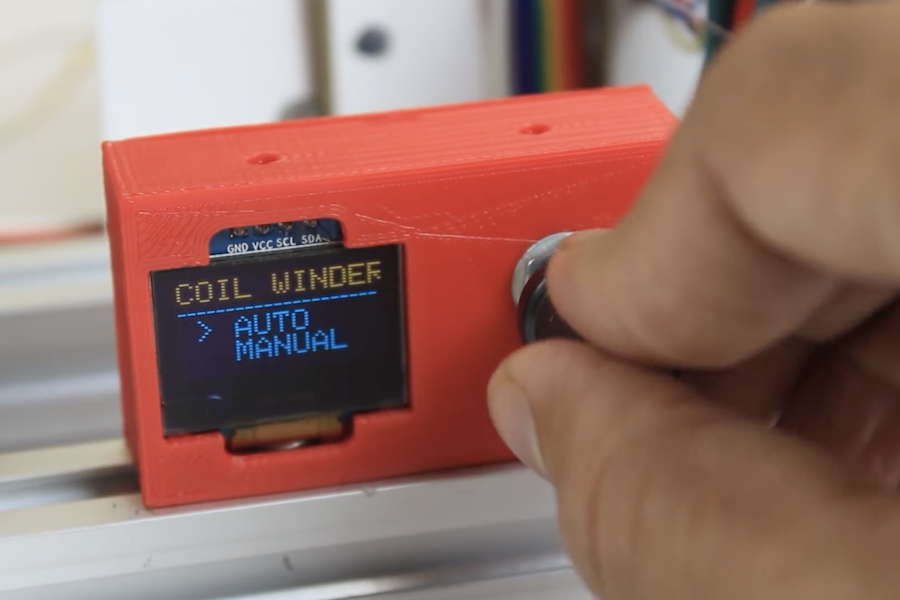

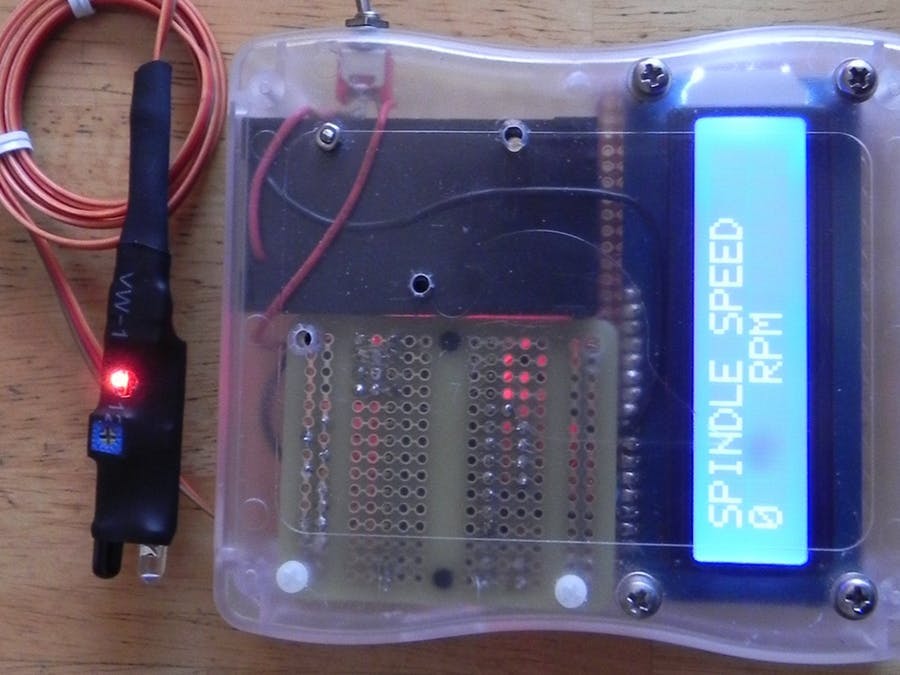

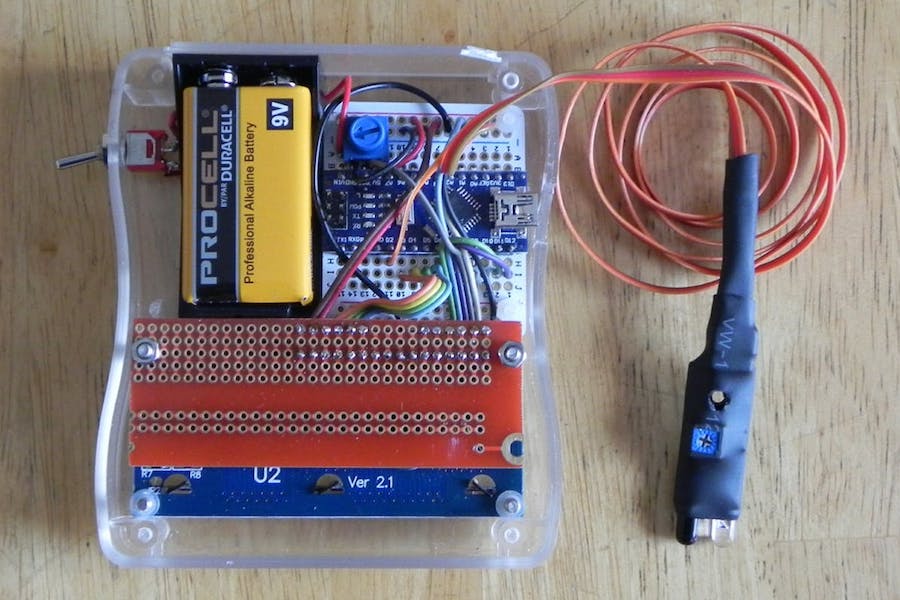

Control is accomplished using infrared sensors that verify page destruction, along with an Arduino that interfaces with the computer running this Unity-based game.

The Book Ritual is a narrative game played using a real book and a real shredder. Your book becomes a character talking to you through the screen. It has a story to tell, but it wants you know your own story too. It asks you to write in its pages and deface it in creative ways to reflect your feelings. The book also needs you to tear out its pages and put them through a shredder.

This is where the custom hardware comes in: the shredder is attached to the computer by a USB cable and detects when paper’s going through it. So, you actually need to shred pages in order to progress.

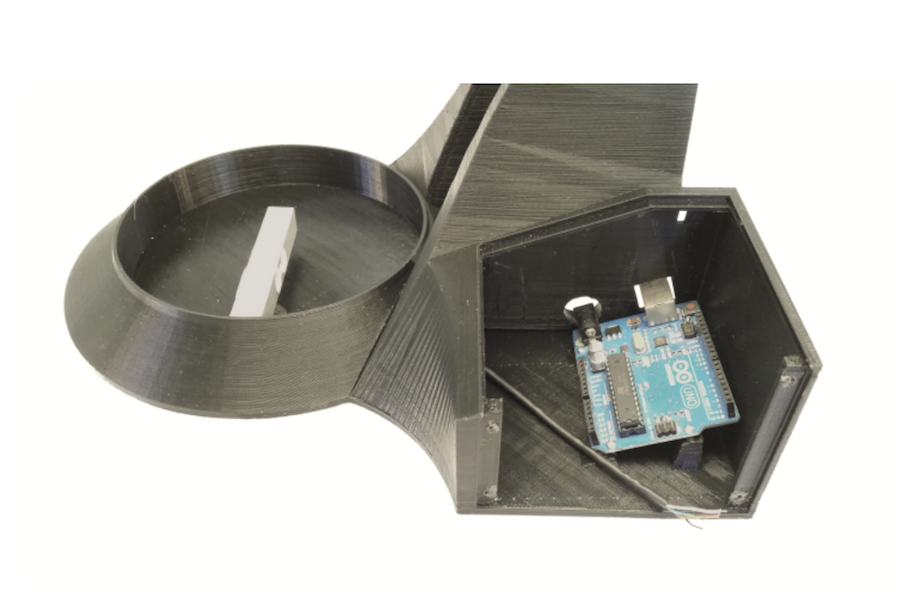

The shredder itself is dressed up as a character, with big cartoon eyes and teeth. Because the subject matter is quite melancholic, I want the player to feel welcomed in by something innocent, childlike and friendly.

More details on the project can be found in Gamasutra’s recent article and on Aichison’s website here.