This post is from Martino Facchin, who is in charge of the firmware development team at Arduino. Hopefully this is the first of a series of posts describing the inner workings of what we do.

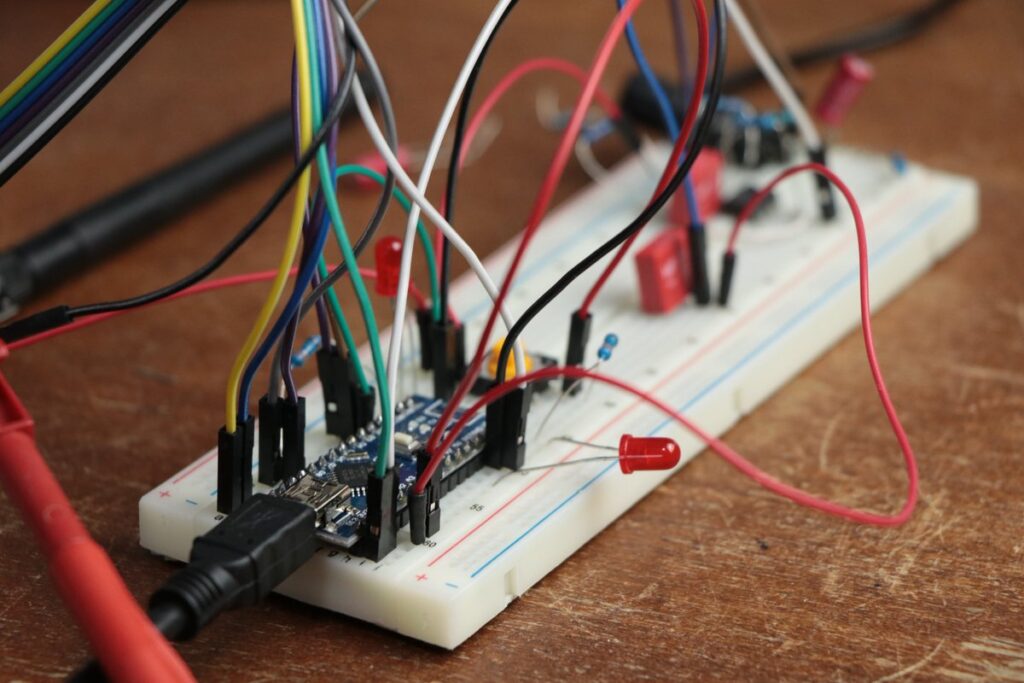

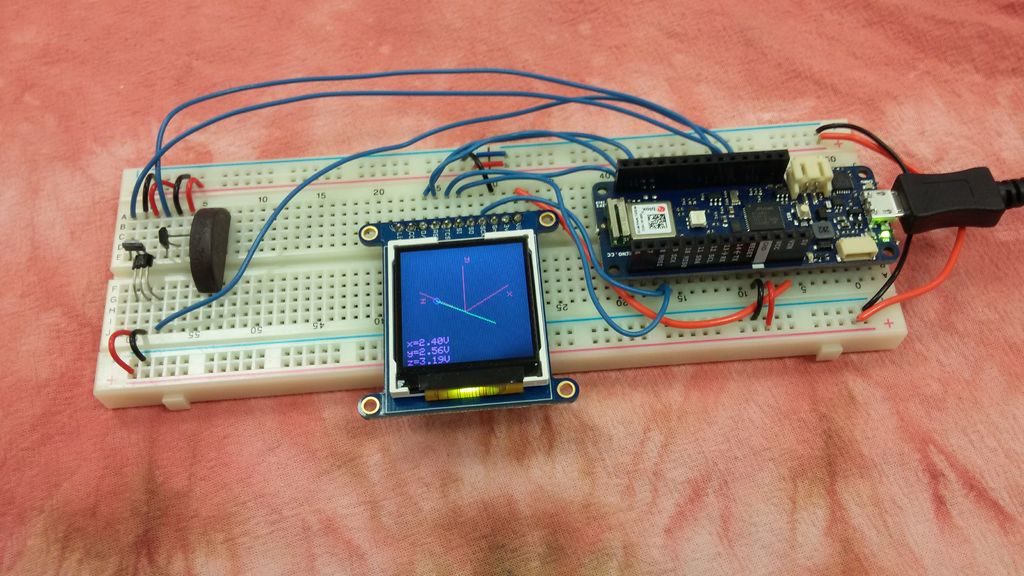

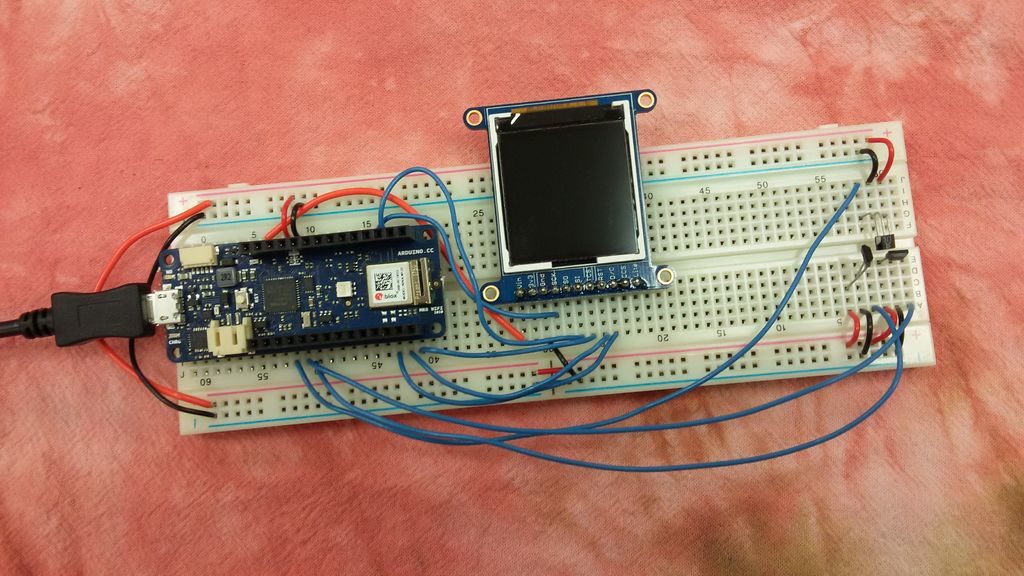

The new, shiny and tiny Nano 33 BLE and Nano 33 BLE Sense are on their way to becoming a serious threat to any hacker’s summer vacation. (I’d recommend spending a couple of days at the lake or beach anyway despite the board’s awesomeness!)

Quoting Sir Isaac Newton (who walked the same streets of Cambridge, UK that the Arm engineers use to get to work everyday), starting from scratch is not always a clever idea. Tens of thousands of man-hours have been spent since the beginning of computer science to reinvent the wheel, sometimes with great results, other times just bringing more fragmentation and confusion.

Since we didn’t have an official Arduino core for the Nordic nRF52840 Cortex-M4 microcontroller, which the Nano 33 BLE and Nano BLE Sense are based upon, we took a look at the various alternatives:

- Using Nordic softdevice infrastructure

- Writing a core from scratch

- Using Mbed OS as a foundation

Option one looks juicy but clashes with a cornerstone of Arduino: open-source software. In fact, softdevice’s closed source approach limits the user’s freedom.

Option two would take a lot of burden on our shoulders for a single board, making the core not very reusable.

So, we went to option three: basing the core on Mbed OS foundation, sharing its drivers and libraries.

As many of you may know, Mbed is a fully preemptive RTOS (real-time operating system), meaning you can run multiple “programs” (more specifically, threads) at the same time, much like what happens in your notebook or smartphone. At Arduino, we have been looking for an RTOS to use on our more advanced boards for a long time but we never found something we liked until we started working with the Mbed OS. Programming an RTOS is usually quite complicated (every university grade course on operating systems will be full of frightening terms like ‘mutex’ and ‘starvation’), but you don’t have to worry if you just want to use it as an Arduino; setup() and loop() are in their usual place, and nobody will mess with your program while it’s running.

But if you want to do MORE, all Mbed infrastructure is there, hidden under the mbed:: namespace. As a side effect of reusing its drivers, we can now support every Mbed board in Arduino with minimal to no effort. Plus, the structure of the core allows any Mbed developer to use Arduino functions and libraries, simply by prepending arduino:: before the actual function call.

Mbed also supports tickless mode; in this way, every time you write delay() in your code, the board will try to go in low power modes, knowing exactly when to wake up for the next scheduled event (or any external interrupt). We are able to achieve an impressive 4.5uA of lower consumption while running a plain old Blink on the Nano 33 BLE (a minimal hardware modification is needed to obtain this value but another blog post is coming). As for Bluetooth support, you can start creating your BLE devices today using the wonderful https://github.com/arduino-libraries/ArduinoBLE but we support plain Cordio APIs as well, in case you need features not yet available in Arduino BLE.

And of course, it’s all open-source!

If you just want to make awesome projects with its plethora of onboard sensors, fire up your Arduino IDE, open the board manager and search for Nano 33 BLE; one click and you are ready to go!

If you want to hack the core, add another Mbed board or merely take a look, your next entry point is the GitHub repo. Don’t be shy if you find a bug or have a suggestion; we love our community, and will try to be as responsive as possible.