Tutorial: Arduino and the MSGEQ7 Spectrum Analyzer

This is a tutorial on using the MSGEQ7 Spectrum Analyser with Arduino, and chapter forty-eight of a series originally titled “Getting Started/Moving Forward with Arduino!” by John Boxall – A tutorial on the Arduino universe. The first chapter is here, the complete series is detailed here.

Updated 10/11/2014

In this article we’re going to explain how to make simple spectrum analysers with an Arduino-style board. (Analyser? Analyzer? Take your pick).

First of all, what is a spectrum analyser? Good question. Do you remember what this is?

It’s a mixed graphic equaliser/spectrum analyser deck for a hi-fi system. The display in the middle is the spectrum analyser, and roughly-speaking it shows the strength of different frequencies in the music being listened to – and looked pretty awesome doing it. We can recreate displays similar to this for entertainment and also as a base for creative lighting effects. By working through this tutorial you’ll have the base knowledge to recreate these yourself.

We’ll be using the MSGEQ7 “seven band graphic equaliser IC” from Mixed Signal Integration. Here’s the MSGEQ7 data sheet (.pdf). This little IC can accept a single audio source, analyse seven frequency bands of the audio, and output a DC representation of each frequency band. This isn’t super-accurate or calibrated in any way, but it works. You can get the IC separately, for example:

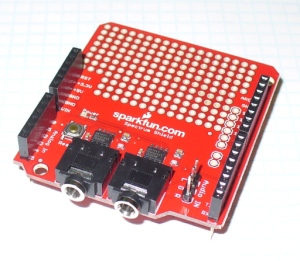

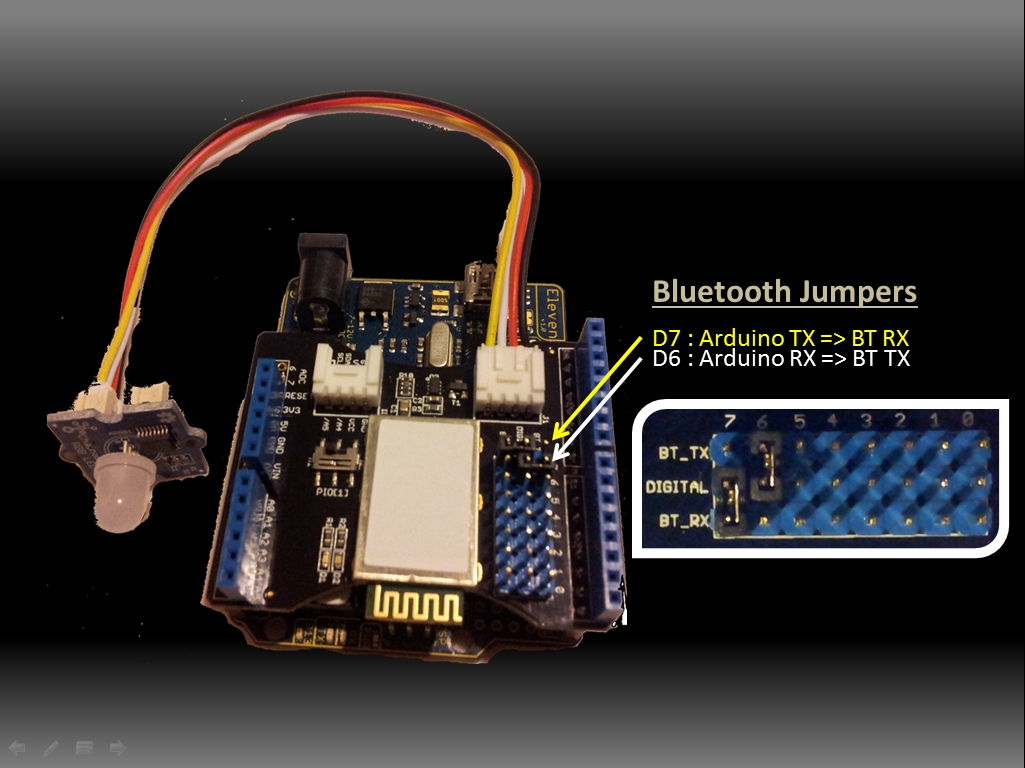

and then build your own circuit around it… or like most things in the Arduino world – get a shield. In this case, a derivative of the original Bliptronics shield by Sparkfun. It’s designed to pass through stereo audio via 3.5mm audio sockets and contains two MSGEQ7s, so we can do a stereo analyser:

As usual Sparkfun have saved a few cents by not including the stackable header sockets, so you’ll need to buy and solder those in yourself. There is also space for three header pins for direct audio input (left, right and common), which are useful – so if you can add those as well.

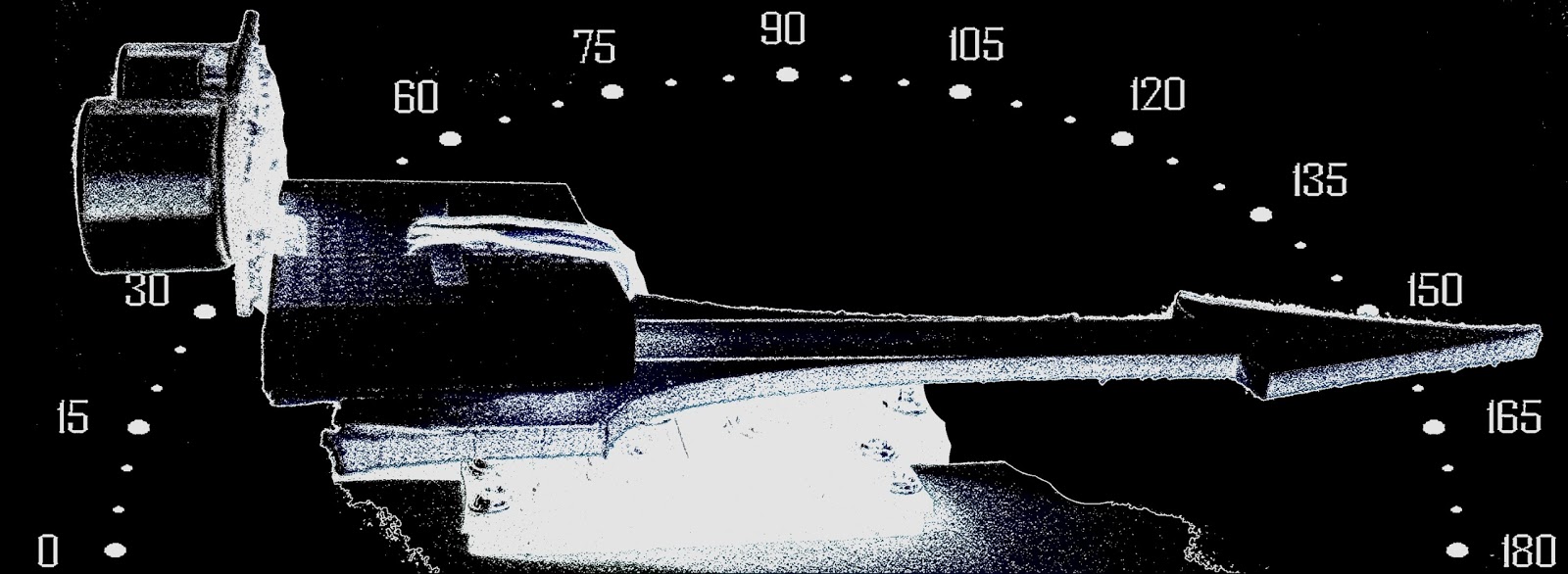

So now you have a shield that’s ready for use. Before moving forward let’s examine how the MSGEQ7 works for us. As mentioned earlier, it analyses seven frequency bands. These are illustrated in the following graph from the data sheet:

It will return the strengths of the audio at seven points – 63 Hz, 160 Hz, 400 Hz, 1 kHz, 2.5 kHz, 6.25 kHz and 16 kHz – and as you can see there is some overlap between the bands. The strength is returned as a DC voltage – which we can then simply measure with the Arduino’s analogue input and create a display of some sort. At this point audio purists, Sheldonites and RF people might get a little cranky, so once again – this is more for visual indication than any sort of calibration device.

However as an 8-pin IC a different approach is required to get the different levels. The IC will sequentially give out the levels for each band on pin 3- e.g. 63 Hz then 160 Hz then 400 Hz then 1 kHz then 2.5 kHz then 6.25 kHz then 16 kHz then back to 63 Hz and so on. To start this sequence we first reset the IC by pulsing the RESET pin HIGH then low. This tells the IC to start at the first band. Next, we set the STROBE pin to LOW, take the DC reading from pin 3 with analogue input, store the value in a variable (an array), then set the STROBE pin HIGH. We repeat the strobe-measure sequence six more times to get the rest of the data, then RESET the IC and start all over again. For the visual learners consider the diagram below from the data sheet:

To demonstrate this process, consider the function

readMSGEQ7()

in the following example sketch:

// Example 48.1 - tronixstuff.com/tutorials > chapter 48 - 30 Jan 2013

// MSGEQ7 spectrum analyser shield - basic demonstration

int strobe = 4; // strobe pins on digital 4

int res = 5; // reset pins on digital 5

int left[7]; // store band values in these arrays

int right[7];

int band;

void setup()

{

Serial.begin(115200);

pinMode(res, OUTPUT); // reset

pinMode(strobe, OUTPUT); // strobe

digitalWrite(res,LOW); // reset low

digitalWrite(strobe,HIGH); //pin 5 is RESET on the shield

}

void readMSGEQ7()

// Function to read 7 band equalizers

{

digitalWrite(res, HIGH);

digitalWrite(res, LOW);

for(band=0; band <7; band++)

{

digitalWrite(strobe,LOW); // strobe pin on the shield - kicks the IC up to the next band

delayMicroseconds(30); //

left[band] = analogRead(0); // store left band reading

right[band] = analogRead(1); // ... and the right

digitalWrite(strobe,HIGH);

}

}

void loop()

{

readMSGEQ7();

// display values of left channel on serial monitor

for (band = 0; band < 7; band++)

{

Serial.print(left[band]);

Serial.print(" ");

}

Serial.println();

// display values of right channel on serial monitor

for (band = 0; band < 7; band++)

{

Serial.print(right[band]);

Serial.print(" ");

}

Serial.println();

}If you follow through the sketch, you can see that it reads both left- and right-channel values from the two MSGEQ7s on the shield, then stores each value in the arrays left[] and right[]. These values are then sent to the serial monitor for display – for example:

If you have a function generator, connect the output to one of the channels and GND – then adjust the frequency and amplitude to see how the values change. The following video clip is a short demonstration of this – we set the generator to 1 kHz and adjust the amplitude of the signal. To make things easier to read we only measure and display the left channel:

Keep an eye on the fourth column of data – this is the analogRead() value returned by the Arduino when reading the 1khz frequency band. You can also see the affect on the other bands around 1 kHz as we increase and decrease the frequency. However that wasn’t really visually appealing – so now we’ll create a small and large graphical version.

First we’ll use an inexpensive LCD, the I2C model from akafugu reviewed previously. To save repeating myself, also review how to create custom LCD characters from here.

With the LCD with have two rows of sixteen characters. The plan is to use the top row for the levels, the left-channel’s on … the left, and the right on the right. Each character will be a little bar graph for the level. The bottom row can be for a label. We don’t have too many pixels to work with, but it’s a compact example:

We have eight rows for each character, and the results from an analogueRead() fall between 0 and 1023. So that’s 1024 possible values spread over eight sections. Thus each row of pixels in each character will represent 128 “units of analogue read” or around 0.63 V if the Arduino is running from true 5 V (remember your AREF notes?). The sketch will again read the values from the MSGEQ7, feed them into two arrays – then display the required character in each band space on the LCD.

Here’s the resulting sketch:

// Example 48.2 - tronixstuff.com/tutorials > chapter 48 - 30 Jan 2013

// MSGEQ7 spectrum analyser shield and I2C LCD from akafugu

// for akafugu I2C LCD

#include "Wire.h"

#include "TWILiquidCrystal.h"

LiquidCrystal lcd(50);

// create custom characters for LCD

byte level0[8] = { 0b00000, 0b00000, 0b00000, 0b00000, 0b00000, 0b00000, 0b00000, 0b11111};

byte level1[8] = { 0b00000, 0b00000, 0b00000, 0b00000, 0b00000, 0b00000, 0b11111, 0b11111};

byte level2[8] = { 0b00000, 0b00000, 0b00000, 0b00000, 0b00000, 0b11111, 0b11111, 0b11111};

byte level3[8] = { 0b00000, 0b00000, 0b00000, 0b00000, 0b11111, 0b11111, 0b11111, 0b11111};

byte level4[8] = { 0b00000, 0b00000, 0b00000, 0b11111, 0b11111, 0b11111, 0b11111, 0b11111};

byte level5[8] = { 0b00000, 0b00000, 0b11111, 0b11111, 0b11111, 0b11111, 0b11111, 0b11111};

byte level6[8] = { 0b00000, 0b11111, 0b11111, 0b11111, 0b11111, 0b11111, 0b11111, 0b11111};

byte level7[8] = { 0b11111, 0b11111, 0b11111, 0b11111, 0b11111, 0b11111, 0b11111, 0b11111};

int strobe = 4; // strobe pins on digital 4

int res = 5; // reset pins on digital 5

int left[7]; // store band values in these arrays

int right[7];

int band;

void setup()

{

Serial.begin(9600);

// setup LCD and custom characters

lcd.begin(16, 2);

lcd.setContrast(24);

lcd.clear();

lcd.createChar(0,level0);

lcd.createChar(1,level1);

lcd.createChar(2,level2);

lcd.createChar(3,level3);

lcd.createChar(4,level4);

lcd.createChar(5,level5);

lcd.createChar(6,level6);

lcd.createChar(7,level7);

lcd.setCursor(0,1);

lcd.print("Left");

lcd.setCursor(11,1);

lcd.print("Right");

pinMode(res, OUTPUT); // reset

pinMode(strobe, OUTPUT); // strobe

digitalWrite(res,LOW); // reset low

digitalWrite(strobe,HIGH); //pin 5 is RESET on the shield

}

void readMSGEQ7()

// Function to read 7 band equalizers

{

digitalWrite(res, HIGH);

digitalWrite(res, LOW);

for( band = 0; band < 7; band++ )

{

digitalWrite(strobe,LOW); // strobe pin on the shield - kicks the IC up to the next band

delayMicroseconds(30); //

left[band] = analogRead(0); // store left band reading

right[band] = analogRead(1); // ... and the right

digitalWrite(strobe,HIGH);

}

}

void loop()

{

readMSGEQ7();

// display values of left channel on LCD

for( band = 0; band < 7; band++ )

{

lcd.setCursor(band,0);

if (left[band]>=895) { lcd.write(7); } else

if (left[band]>=767) { lcd.write(6); } else

if (left[band]>=639) { lcd.write(5); } else

if (left[band]>=511) { lcd.write(4); } else

if (left[band]>=383) { lcd.write(3); } else

if (left[band]>=255) { lcd.write(2); } else

if (left[band]>=127) { lcd.write(1); } else

if (left[band]>=0) { lcd.write(0); }

}

// display values of right channel on LCD

for( band = 0; band < 7; band++ )

{

lcd.setCursor(band+9,0);

if (right[band]>=895) { lcd.write(7); } else

if (right[band]>=767) { lcd.write(6); } else

if (right[band]>=639) { lcd.write(5); } else

if (right[band]>=511) { lcd.write(4); } else

if (right[band]>=383) { lcd.write(3); } else

if (right[band]>=255) { lcd.write(2); } else

if (right[band]>=127) { lcd.write(1); } else

if (right[band]>=0) { lcd.write(0); }

}

}If you’ve been reading through my tutorials there isn’t anything new to worry about. And now for the demo, with sound –

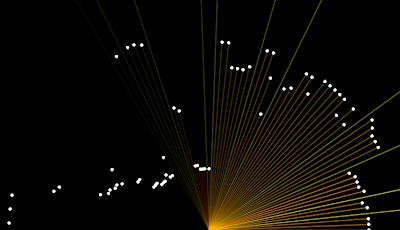

That would look great on the side of a Walkman, however it’s a bit small. Let’s scale it up by using a Freetronics Dot Matrix Display – you may recall these from Clock One. For some background knowledge check the review here. Don’t forget to use a suitable power supply for the DMD – 5 V at 4 A will do nicely. The DMD contains 16 rows of 32 LEDs. This gives us twice the “resolution” to display each band level if desired. The display style is subjective, so for this example we’ll use a single column of LEDs for each frequency band, with a blank column between each one.

We use a lot of line-drawing statements to display the levels, and clear the DMD after each display. With this and the previous sketches, there could be room for efficiency – however I write these with the beginner in mind. Here’s the sketch:

// Example 48.3 - tronixstuff.com/tutorials > chapter 48 - 30 Jan 2013

// MSGEQ7 spectrum analyser shield with a Freetronics DMD

// for DMD

#include "DMD.h" // for DMD

#include "SPI.h" // SPI.h must be included as DMD is written by SPI (the IDE complains otherwise)

#include "TimerOne.h"

#include "SystemFont5x7.h" // keep next two lines if you want to add some text

#include "Arial_black_16.h"

DMD dmd(1, 1); // creates instance of DMD to refer to in sketch

void ScanDMD() // necessary interrupt handler for refresh scanning of DMD

{

dmd.scanDisplayBySPI();

}

int strobe = 4; // strobe pins on digital 4

int res = 5; // reset pins on digital 5

int left[7]; // store band values in these arrays

int right[7];

int band;

void setup()

{

// for DMD

//initialize TimerOne's interrupt/CPU usage used to scan and refresh the display

Timer1.initialize( 5000 ); //period in microseconds to call ScanDMD. Anything longer than 5000 (5ms) and you can see flicker.

Timer1.attachInterrupt( ScanDMD ); //attach the Timer1 interrupt to ScanDMD which goes to dmd.scanDisplayBySPI()

dmd.clearScreen( true ); //true is normal (all pixels off), false is negative (all pixels on)

// for MSGEQ7

pinMode(res, OUTPUT); // reset

pinMode(strobe, OUTPUT); // strobe

digitalWrite(res,LOW); // reset low

digitalWrite(strobe,HIGH); //pin 5 is RESET on the shield

}

void readMSGEQ7()

// Function to read 7 band equalizers

{

digitalWrite(res, HIGH);

digitalWrite(res, LOW);

for( band = 0; band < 7; band++ )

{

digitalWrite(strobe,LOW); // strobe pin on the shield - kicks the IC up to the next band

delayMicroseconds(30); //

left[band] = analogRead(0); // store left band reading

right[band] = analogRead(1); // ... and the right

digitalWrite(strobe,HIGH);

}

}

void loop()

{

int xpos;

readMSGEQ7();

dmd.clearScreen( true );

// display values of left channel on DMD

for( band = 0; band < 7; band++ )

{

xpos = (band*2)+1;

if (left[band]>=895) { dmd.drawLine( xpos, 15, xpos, 1, GRAPHICS_NORMAL ); } else

if (left[band]>=767) { dmd.drawLine( xpos, 15, xpos, 3, GRAPHICS_NORMAL ); } else

if (left[band]>=639) { dmd.drawLine( xpos, 15, xpos, 5, GRAPHICS_NORMAL ); } else

if (left[band]>=511) { dmd.drawLine( xpos, 15, xpos, 7, GRAPHICS_NORMAL ); } else

if (left[band]>=383) { dmd.drawLine( xpos, 15, xpos, 9, GRAPHICS_NORMAL ); } else

if (left[band]>=255) { dmd.drawLine( xpos, 15, xpos, 11, GRAPHICS_NORMAL ); } else

if (left[band]>=127) { dmd.drawLine( xpos, 15, xpos, 13, GRAPHICS_NORMAL ); } else

if (left[band]>=0) { dmd.drawLine( xpos, 15, xpos, 15, GRAPHICS_NORMAL ); }

}

// display values of right channel on DMD

for( band = 0; band < 7; band++ )

{

xpos = (band*2)+18;

if (right[band]>=895) { dmd.drawLine( xpos, 15, xpos, 1, GRAPHICS_NORMAL ); } else

if (right[band]>=767) { dmd.drawLine( xpos, 15, xpos, 3, GRAPHICS_NORMAL ); } else

if (right[band]>=639) { dmd.drawLine( xpos, 15, xpos, 5, GRAPHICS_NORMAL ); } else

if (right[band]>=511) { dmd.drawLine( xpos, 15, xpos, 7, GRAPHICS_NORMAL ); } else

if (right[band]>=383) { dmd.drawLine( xpos, 15, xpos, 9, GRAPHICS_NORMAL ); } else

if (right[band]>=255) { dmd.drawLine( xpos, 15, xpos, 11, GRAPHICS_NORMAL ); } else

if (right[band]>=127) { dmd.drawLine( xpos, 15, xpos, 13, GRAPHICS_NORMAL ); } else

if (right[band]>=0) { dmd.drawLine( xpos, 15, xpos, 15, GRAPHICS_NORMAL ); }

}

}… and here it is in action:

Conclusion

At this point you have the knowledge to use the MSGEQ7 ICs to create some interesting spectrum analysers for entertainment and visual appeal – now you just choose the type of display enjoy the results. And if you enjoyed this article, or want to introduce someone else to the interesting world of Arduino – check out my book (now in a fourth printing!) “Arduino Workshop”.

Have fun and keep checking into tronixstuff.com. Why not follow things on twitter, Google+, subscribe for email updates or RSS using the links on the right-hand column, or join our forum – dedicated to the projects and related items on this website.

The post Tutorial: Arduino and the MSGEQ7 Spectrum Analyzer appeared first on tronixstuff.